How to Design a Mobile Kitchen for Fast Food Operations | Expert Guide

The rise of mobile kitchens has revolutionized the fast-food industry, offering flexibility, cost efficiency, and scalability. Whether it's a food court stall, a small commercial kitchen in a repurposed shipping container, or a mobile commercial kitchen on wheels, these setups cater to modern consumers who prioritize convenience. According to industry reports, the global mobile kitchen market is projected to grow by 8.2% annually through 2028, driven by demand for fast food container solutions and pop-up dining experiences. Designing an effective mobile kitchen requires balancing functionality, space optimization, and brand alignment—key factors we'll explore below.

Selecting the Right Fast-Food Concept for Your Mobile Kitchen

Choosing the right fast-food concept is critical for success in a competitive market. Mobile kitchens thrive on speed and simplicity, making concepts like gourmet burgers, tacos, or coffee bars ideal due to their streamlined menus and high turnover rates. For instance, a design fast food restaurant focusing on handheld meals can reduce equipment complexity while maximizing output. Market viability is equally important: analyze local demographics and trends—urban areas might favor health-conscious bowls, while event-driven locations could prioritize comfort foods. Aligning your concept with proven demand ensures your tiny commercial kitchen remains profitable and adaptable.

Assessing Market Demand and Viability

Before investing in a prefabricated kitchen, conduct thorough market research. Identify gaps in local offerings, such as late-night snacks or allergen-free options, and assess foot traffic patterns. For example, a mobile commercial kitchen near office hubs might focus on quick lunches, while one at music festivals could emphasize shareable snacks. Utilize tools like surveys or social media analytics to validate your concept's appeal.

Matching Your Brand Identity to Your Mobile Kitchen Design

Your kitchen's design should reflect your brand's personality. A retro-themed fast food container might use bold colors and vintage signage, while a health-focused industrial kitchen container could opt for minimalist aesthetics with eco-friendly materials. Consistency in branding—from logo placement to packaging—enhances recognition and customer loyalty.

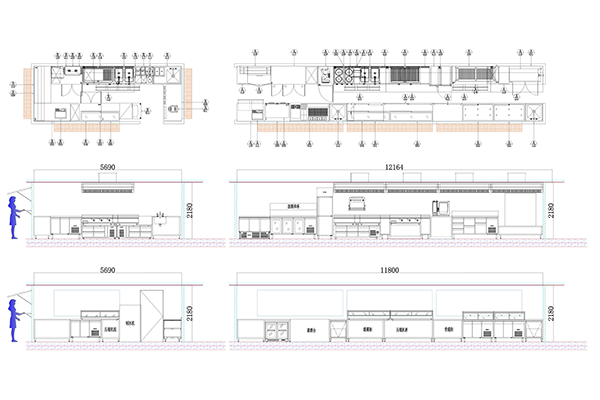

Essential Layout Considerations for a Mobile Fast-Food Kitchen

Key equipment for a fast food kitchen includes:

Griddles/Flat-Tops: Ideal for burgers and pancakes, offering even heat distribution and quick cleanup.

Compact Fryers: Space-saving units with rapid oil recovery for high-volume frying.

Convection Ovens: Multi-functional for baking, roasting, and reheating, essential for diverse menus.

Portable Induction Cooktops: Energy-efficient and safe for tight spaces.

Maximize vertical space with shelving and hanging racks for utensils. Use modular bins for dry goods and under-counter refrigeration for perishables. In tiny commercial kitchens, sliding drawers and foldable tables add flexibility without cluttering the workspace.

Food Prep Zone

Stainless steel countertops are durable and easy to sanitize. Designate separate areas for raw and cooked ingredients to prevent cross-contamination. Incorporate hands-free fixtures like foot-pedal sinks to uphold hygiene standards.

Dishwashing Area

Install a two-compartment sink with a commercial-grade sprayer for quick cleaning. For mobile kitchens, consider portable dishwasher units that fit into tight corners while meeting health regulations.

Cost Considerations in Building a Mobile Kitchen

Initial investments for a commercial kitchen container range from $20,000 to $100,000, depending on customization. Prefabricated units reduce construction costs by up to 30%, while energy-efficient equipment lowers long-term utility expenses. Prioritize durable materials and multi-functional appliances to minimize maintenance and replacement costs.

Breaking Down the Investment: Containers, Equipment, and Customization

Shipping containers typically cost $5,000–$15,000, with modifications (plumbing, electrical) adding $10,000–$30,000. High-quality equipment accounts for 40–50% of the budget, while permits and licensing vary by region.

Maintenance Tips for a Long-Lasting Mobile Kitchen

Shipping container-based mobile kitchens face unique challenges due to their compact design, exposure to varying climates, and frequent transportation. Factors like corrosion (especially in steel containers), structural stress from vibrations during transit, moisture buildup leading to mold or rust, wear-and-tear on equipment, and poor hygiene practices can significantly reduce their lifespan. Below are five essential maintenance tips to ensure durability and operational efficiency:

Inspect Structural Integrity Regularly

Check welding points, door hinges, and corner castings for cracks or rust, as steel containers are prone to corrosion. Reinforce loose bolts and inspect portable locking mechanisms (twist locks) to prevent structural failures during transport.

Protect Against Moisture and Corrosion

Apply anti-corrosion coatings to exterior surfaces and seal gaps with waterproofing materials. Use desiccants like container-specific drying strips to control humidity inside, preventing mold and metal degradation.

Maintain HVAC and Ventilation Systems

Clean HVAC filters monthly to ensure airflow efficiency and prevent overheating. For refrigerated units, defrost cooling coils regularly and verify air circulation rates (30–40 air changes/hour for low-temperature units) to avoid ice buildup and equipment strain.

Service Grease Traps and Plumbing

Clean grease traps weekly to prevent clogs and odors, and insulate pipes in cold climates to avoid freezing. Use CE-certified, stainless steel equipment for durability and easier sanitation.

Deep Clean and Sanitize Surfaces

Schedule biweekly deep cleaning of prep areas, stainless steel countertops, and storage zones with food-safe disinfectants. Focus on joints and crevices where residue accumulates, reducing bacterial growth and compliance risks

Realizing Your Mobile Kitchen Vision with Shinelong

Shinelong excels in delivering turnkey solutions for industrial kitchen containers and prefabricated kitchens, with customizable designs perfect for fast-food operations. We handle everything from layout planning and equipment sourcing to compliance support, ensuring your mobile kitchen meets operational and regulatory standards. Our expertise in MEPs—mechanical, electrical, and plumbing—guarantees compliance and efficiency, while our showroom showcases prototypes with features like certified gear racks and optimal airflow setups. We specialize in bespoke layouts that maximize space without compromising on code specs, helping you reduce setup time by 50%. Trust Shinelong to handle the details, whether you're setting up a prefabricated kitchen or a custom rig. Your taco truck or burger pod will run efficiently, backed by professionals dedicated to mobile kitchen design. Contact us today to bring your vision to life with reliable, efficient solutions.

Since SHINELONG was established in Guangzhou in 2008, we have made great strides in the fields of commercial kitchen planning and kitchen equipment manufacturing.

IF YOU HAVE ANY QUESTION,PLEASE CONTACT US.

WhatsApp: +8618902337180

WeChat: +8618924185248

Telephone: 20-34709971

Fax: +86 20 34709972

Email: info@chinashinelong.com

After-Sales Contact

Whatsapp :+8619195343796

Email: service@chinashinelong.com

Add: No. 1 Headquarters Center, Tian An Hi-tech Ecological Park, Panyu Avenue, Guangzhou, China.