How to Build a High-Performance Commercial Kitchen in a Shipping Container | Ultimate Modular Kitchen Solution

The concept of a commercial container kitchen is increasingly popular. However, designing a functional and efficient kitchen within a shipping container, while also creating a comfortable and productive layout, presents unique challenges for those starting a modular kitchen business. If you're wondering how to launch your own shipping container kitchen, don't worry! This article will guide you through the entire process of setting up a commercial kitchen in a shipping container. Let's dive in!

What is a Commercial Shipping Container Kitchen?

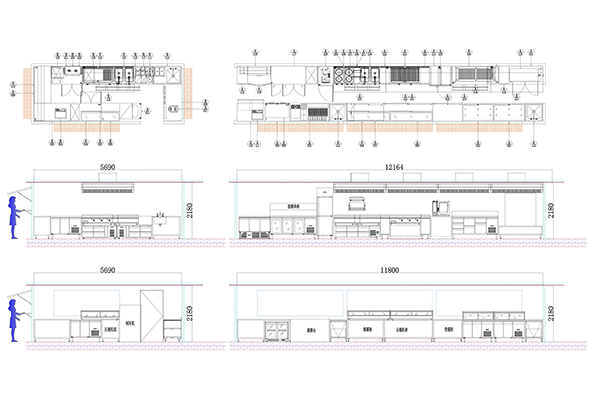

A container kitchen, also referred to as a modular kitchen or shipping container kitchen, is a portable, self-contained kitchen unit built inside a standard shipping container. Typically, these shipping container kitchens range in size from 20ft (5.9×2.3×2.3m) to 40ft (12×2.3×2.3m). Designed for easy transport and deployment, they offer a flexible and efficient solution for food preparation and service in various locations. In today's rapidly changing culinary world, the commercial shipping container kitchen has become a transformative solution. Compared to traditional kitchen construction, they present a cost-effective and eco-friendly alternative, offering the added advantages of portability and scalability. With EU FUND 2021-2027 subsidies of up to 30% available for modular kitchen projects, a container kitchen project is an excellent choice for aspiring kitchen entrepreneurs.

The definition and key advantages of a container kitchen

At its core, a shipping container kitchen represents a smart transformation: taking those ubiquitous steel boxes, ranging from 20 to 40 feet, and turning them into fully equipped, modular commercial kitchens. We're not just talking about a basic cookspace here. These are sophisticated culinary environments, complete with seamlessly integrated, professional-grade cooking equipment and, increasingly, intelligent management systems to streamline operations. Now, let's be clear – compared to traditional kitchens, this modular design offers a compelling array of advantages that any restaurateur or food service operator should seriously consider.

• Rapid Deployment: From Site to Sizzle in Half the Time

Forget agonizing months of construction delays! Container kitchens redefine speed. Thanks to pre-fabricated modular construction, these units arrive largely complete. On-site installation is a breeze, slashing setup time by up to 50% compared to traditional builds. That means you're flipping burgers and ringing up sales weeks, if not months, sooner. In today's fast-paced culinary landscape, that speed advantage translates directly to a healthier bottom line and a quicker return on investment. For pop-up ventures or rapidly expanding chains, this accelerated timeline is nothing short of revolutionary. It's not just about speed; it's about seizing opportunities.

• Scalable Flexibility: Grow Your Kitchen, Grow Your Business

Your culinary ambitions shouldn't be constrained by fixed walls! The modular nature of shipping container kitchens provides unparalleled flexibility. Need more prep space? Simply add another container. Expanding your menu and require specialized equipment? Integrate a new modular kitchen unit seamlessly. The ability to stack and combine multiple containers allows you to adapt to evolving business demands without the headache and expense of major renovations. This scalability isn't just a convenience; it's a strategic advantage, allowing you to right-size your kitchen as your business flourishes, minimizing wasted space and maximizing efficiency.

• Cost-Effective Construction: Slash Expenses, Not Quality

Let's talk turkey – or rather, let's talk smart spending. Container kitchens offer a dramatically more affordable path to launching or expanding your culinary operations. Construction costs typically run 30% to 50% lower than traditional builds. This isn't about cutting corners; it's about intelligent resource allocation. The streamlined pre-fabrication process minimizes labor costs, reduces material waste, and accelerates the entire project timeline. The savings extend beyond initial construction. Container kitchens often qualify for accelerated depreciation, further boosting your bottom line. Invest those savings back into your menu, marketing, or top-tier talent – the areas that truly drive success.

• Eco-Conscious Construction: Serve Up Sustainability

In today's environmentally aware market, sustainability is more than a buzzword – it's a business imperative. Container kitchens offer a genuinely eco-friendly solution. A remarkable 85% of the materials are recycled steel, drastically reducing the environmental impact compared to traditional construction. By repurposing shipping containers, you're diverting waste from landfills and minimizing the demand for new building materials. Moreover, the modular design minimizes on-site construction waste. By choosing a container kitchen, you're not just building a business; you're building a greener future. This commitment to sustainability resonates with today's conscious consumers, enhancing your brand image and attracting a loyal customer base.

• Mobile Convenience: Kitchens on the Go

Imagine the freedom to bring your culinary creations directly to your customers, wherever they may be. Shipping container kitchens offer unparalleled mobility. Whether it's setting up shop at a bustling music festival, providing essential catering services in disaster-stricken areas, or establishing a unique dining experience in a scenic tourist destination, these kitchens can go virtually anywhere. The ability to transport the entire unit intact eliminates the need for costly and time-consuming on-site construction. This mobility isn't just a logistical advantage; it's a powerful marketing tool, allowing you to tap into new markets and generate buzz with a truly unique culinary experience.

The 4 classic application scenarios of container kitchen

• Street Culinary New Wave: Container Kitchens Redefining City Dining

Forget the stuffy, formal restaurants—because the street food scene is being revolutionized by container kitchens! Imagine trendy pop-up cafes and vibrant food markets, all powered by these versatile units. Ingenious fold-out bar extensions boost space by a staggering 60%, while smart order screens link directly to high-performance coffee machines. It's like having a deli on wheels right there on the street. You can just walk up and order your favorite street food on the spot. Isn't this kind of dining experience way more vibrant and exciting than sitting in a restaurant? The commercial kitchen landscape has been changed.

• Mega-Event Powerhouse: Container Kitchens for Peak Performance

Picture this: a music festival with tens of thousands of hungry fans, and a commercial kitchen system that needs to materialize in 72 hours. The solution? A modular container kitchen matrix (think 6 x 40ft units) equipped with a central ventilation tower and intelligent food distribution lines. These systems can churn out a staggering 2,000 standardized meals per hour! This isn't just about feeding the masses; it's about logistics mastery. Container kitchens are proving themselves as the ultimate rapid-deployment commercial kitchen solution for any large-scale event.

• Service Outpost Pioneers: Container Kitchens Where They're Needed Most

When infrastructure is limited or non-existent, container kitchens step up as service pioneers. Key technologies include off-grid power systems (solar + diesel hybrid) and mobile water purification units capable of processing 8 tons daily. These self-sufficient commercial kitchen units can provide essential food services in remote locations, disaster zones, or anywhere in need of reliable support. Container kitchens aren't just about convenience; they're about delivering critical resources where they're needed most, offering a lifeline in challenging circumstances. They redefine the very concept of a commercial kitchen.

• Future Kitchen Lab: Container Kitchens Pushing Culinary Boundaries

Step into the future of food with container kitchens serving as innovation hubs. Envision smart cooking islands powered by AI visual recognition, using robotic arms for precise temperature control (±1℃) and automated ingredient dispensing. This is where culinary artistry meets cutting-edge technology! Container kitchens are becoming laboratories for experimentation, pushing the boundaries of what's possible in a commercial kitchen. It represents a bold step toward the future of food production and service. It represents the fusion of technology and commercial kitchen innovation.

Step-by-Step Guide to Building Your Shipping Container Kitchen

1. Planning and Design: From Needs to Blueprints

In the intricate world of commercial kitchen design, the planning phase for a container kitchen is a delicate negotiation between available space and operational efficiency. It's about more than just fitting equipment into a metal box; it's about crafting a functional and profitable culinary environment.

The first step involves a thorough needs diagnosis. This means accurately predicting your daily meal output based on your specific culinary style – whether you're envisioning a fast-paced burger joint, a delicate pastry shop, or a high-volume central kitchen. For example, calculating that X number of simple meals will require Y specific equipment and a Z kilowatt electrical load is crucial. Then there's the workflow revolution. I always advocate for adopting the European EN 1627 standard "Golden Triangle" layout, which prioritizes minimizing chef movement. By ensuring that each cook's path is no more than 5 meters, you can boost efficiency by a remarkable 40%.

And of course, a compliance blueprint is non-negotiable. This involves pre-planning for essential elements like exhaust shafts, ensuring they have a cross-section of at least 0.5 square meters, and fire zones with a fire resistance of at least 1 hour. Securing pre-approval from local health departments is also a must.

2. Container Preparation and Modification

The conversion of a standard shipping container is the technological heart of bringing any modular kitchen vision to life. It's where raw potential transforms into functional reality. The first crucial step is careful container selection. Prioritize the container material, considering factors like durability, insulation properties, and resistance to corrosion. What dimensions will best suit your specific commercial application? A sprawling 40-foot container might be perfect for a full-service restaurant, while a more compact 20-footer could be ideal for a smaller cafe or a mobile catering operation.

Structural engineering is equally vital. Reinforce the container to withstand the demands of a busy commercial kitchen. This often involves adding top-load truss supports to ensure a load-bearing capacity of at least 800 kilograms per square meter. The floor should be covered with a durable, non-slip material like 3mm aluminum with a friction coefficient of 0.85. Then, there's the environmental systems, which are important to protect all the employees and customer base.

3. Integration of Professional Kitchen Equipment

Selecting and integrating the right professional kitchen equipment is paramount to building a truly high-performance commercial kitchen. This process must be guided by what I call the "3S Principle": Smart, Sustainable, and Scalable. Smart equipment leverages technology to enhance efficiency and streamline operations. Sustainable equipment minimizes environmental impact and reduces operating costs. Scalable equipment can adapt to changing business needs and accommodate future growth. When it comes to core equipment, I recommend considering specific pieces for each key zone.

Shinelong cooking equipment, known for its exceptional 25% energy savings, is a smart choice for the cooking zone. In the cleaning zone, a high-pressure water jet dishwasher, which can slash water consumption by 40%, is a sustainable solution. And for the storage zone, Furnotel refrigerators, with their incredibly precise temperature control (fluctuations of just ±0.3℃), ensure optimal food preservation.

4. Customized Decoration and Brand Presentation

In today's competitive culinary landscape, branding is more than just a logo – it's an amplifier of commercial value, a way to create a lasting impression on your customers. That's why customized decoration and brand presentation are so essential for container kitchens. It starts with the facade revolution. Consider laser-engraving your company logo directly onto the container's exterior to a depth of 0.8 millimeters for a permanent and professional look. Add a magnetic light box with a brightness of 5000 candelas per square meter to ensure visibility up to 200 meters at night. Don't underestimate the power of spatial magic.

A quick-install wall system allows you to completely transform the interior's aesthetic in a matter of hours, switching from an industrial-chic vibe to a minimalist Scandinavian design with ease. Smart glass partitions, featuring electrically controlled atomization, enable instantaneous transitions between open and closed layouts, providing flexibility for different service styles and events. Remember, your commercial kitchen is more than just a place to cook; it's an extension of your brand.

Ready to Set Up a Container Kitchen for Your Business?

After reading this article, you must have gained a basic understanding of container kitchens. However, building the perfect container kitchen based solely on this article would be insufficient. To turn your dream commercial kitchen into reality, the best approach is to find a reliable partner.

As a leading brand in one-stop commercial kitchen solutions across Asia, we have the qualifications to cover all the kitchen needs you could ever require. Shinelong offers a comprehensive range of food service solutions, including hotels, fine-dining restaurants, fast-food outlets, bakeries, hospitals, schools, central kitchens, and modular kitchen. We have consistently maintained our company's pristine image by prioritizing our customers and are committed to continuously improving our business practices and providing the best solutions for all F&B developers.

Shinelong handles a complete end-to-end business process, covering pre-sales, sales, and after-sales services. Whether you are looking to innovate, expand, or simply streamline your operations, we are here to support you every step of the way. Reach out to us today to bring your culinary vision to life.

-

Is it cheaper to build in a container?It all depends on the complexity of the design. But if it's a very simple design with little modifications to the containers themselves, then it's very cheap! Even with a few simple modifications, the cost is still much cheaper than building a house out of timber or concrete.

-

Which type of container is best for a kitchen?Stainless steel is an inert material that doesn't react with food stuff. This makes stainless steel jars the best kitchen storage containers.

-

Can you convert a shipping container into a kitchen?YES! As a leading brand in one-stop commercial kitchen solutions across Asia, we have the qualifications to cover all the kitchen needs you could ever require. The comprehensive kitchen solutions we offer go beyond just shipping container kitchens. We can provide a full range of services for setting up any type of kitchen, including those for hotels, fine-dining restaurants, fast-food outlets, bakeries, hospitals, schools, central kitchens, and modular kitchens. By prioritizing our customers, we have consistently maintained our company's pristine image. We are committed to continuously improving our business practices and delivering the best solutions for all F&B developers.

-

Where do you have local support?In UAE,Saudi Arabia,Thailand,Vietnam,Indonesia,Cambodia,Tanzania, Mauritius, Reunion,we can provide local support

-

Are you manufacturer?Yes,we are half manufacturer half trading company. Manufacturing Furnotel brand equipment, trading for all kinds of kitchen equipment,especially turn-key solution.

Since SHINELONG was established in Guangzhou in 2008, we have made great strides in the fields of commercial kitchen planning and kitchen equipment manufacturing.

IF YOU HAVE ANY QUESTION,PLEASE CONTACT US.

WhatsApp: +8618902337180

WeChat: +8618924185248

Telephone: 20-34709971

Fax: +86 20 34709972

Email: info@chinashinelong.com

After-Sales Contact

Whatsapp :+8619195343796

Email: service@chinashinelong.com

Add: No. 1 Headquarters Center, Tian An Hi-tech Ecological Park, Panyu Avenue, Guangzhou, China.