In healthcare facilities, the kitchen is more than a food production hub—it's a critical component of patient care, safety, and recovery.

How to Design a Hospital Kitchen: A Guide to Healthcare Foodservice

In healthcare facilities, the kitchen is more than a food production hub—it's a critical component of patient care, safety, and recovery. Unlike generic commercial kitchens, hospital kitchens must balance high-volume meal preparation with strict hygiene standards, specialized dietary needs, and compliance with healthcare regulations. This guide explores best practices for designing a hospital kitchen that optimizes efficiency, minimizes cross-contamination risks, and supports the unique demands of healthcare foodservice.

Defining Objectives & Scope for Healthcare Foodservice

Hospital kitchens serve diverse populations, including inpatients, outpatients, assisted living residents, and rehabilitation units. Unlike standard commercial kitchens, their primary goals extend beyond speed and cost-efficiency. Key objectives include:

-

Nutritional precision: Delivering meals tailored to medical conditions—for example, low-sodium or diabetic-friendly diets.

-

Timely delivery: Ensuring food reaches patients within FDA Food Code-recommended temperature thresholds.

-

Regulatory compliance: Adhering to HACCP principles, FDA guidelines, and local healthcare regulations at the hospital location.

By clarifying these priorities early, designers can align workflows and equipment with the needs of healthcare facilities.

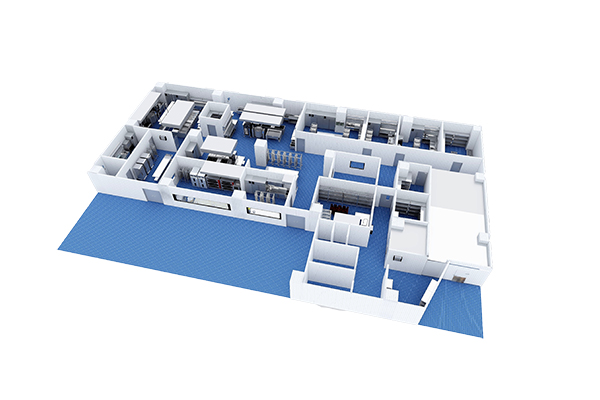

Optimizing Functional Zones & Workflow

A hospital kitchen's layout should separate high-risk tasks to prevent cross-contamination while maintaining seamless workflow:

-

Receiving & Storage:

-

Inspect ingredients for quality and allergen risks.

-

Use segregated cold storage for raw proteins, dairy, and ready-to-eat items.

-

-

Preparation & Cooking:

-

Equip zones with combi ovens (steam/convection hybrid) for flexible cooking.

-

Integrate sous-vide systems for precise, nutrient-preserving meal preparation.

-

-

Plating & Distribution:

-

Design dedicated tray assembly lines with heated holding cabinets.

-

Use insulated delivery carts or room-service models for food delivery to hospital rooms.

-

-

Warewashing & Sanitation:

-

Install pass-through dishwashers to separate clean/dirty zones.

-

Position hand-hygiene stations at key workflow intersections.

-

![Hospital Kitchens 3D Floor Plan]()

-

Selecting Equipment for Healthcare Foodservice

Hospital kitchens require specialized commercial kitchen equipment to meet safety and efficiency demands:

-

Cooking: Commercial cooking equipment is an indispensable unit of every professional kitchen. Considering the importance of meal hygiene and nutritional health, the induction cooker has become essential to healthcare foodservice operations.

-

Holding & Delivery: Heated cabinets maintain meals at 57℃+ to comply with food safety standards.

-

Packaging: Chamber vacuum sealers extend shelf life for pre-portioned meals.

-

Cleaning: High-temperature dishwashers with chemical sanitization cycles eliminate pathogens.

Prioritize NSF-certified equipment to ensure compliance with healthcare-grade hygiene requirements.

Preventing Cross-Contamination in Healthcare Kitchens

Healthcare foodservice faces heightened contamination risks due to immunocompromised patients. Mitigate threats with:

-

HACCP integration: Document critical control points for receiving, cooking, and plating.

-

Color-coded tools: Assign specific colors to allergen-free zones and raw/cooked food stations.

-

Touchless fixtures: Automated faucets and foot-pedal trash bins reduce surface contact.

-

Staff training: Enforce glove-changing protocols between tasks and zones.

-

![cold storage area]()

Enhancing Ergonomics & Staff Efficiency

Fatigued staff are more prone to errors. Optimize workflows with:

-

NSF/ANSI-compliant layouts: Maintain 48-inch aisle widths for unobstructed movement.

-

Adjustable workstations: Reduce strain during repetitive tasks like vegetable prep.

-

Digital tools: Real-time inventory systems cut manual stock checks by 50%.

-

![essencial hospital kitchen equipment list]()

Designing for Scalability & Sustainability

As healthcare facilities expand, kitchens must adapt:

-

Modular layouts: Pre-plumbed zones simplify future upgrades for assisted living or satellite units.

-

Preventive maintenance: Schedule quarterly inspections for commercial kitchen equipment to avoid downtime.

-

Energy efficiency: ENERGY STAR-rated appliances lower utility costs, while compost stations align with hospital sustainability goals.

Find the Trusted Partner to Help You Design an Efficient Hospital Kitchen

Designing a hospital kitchen that meets the rigorous demands of healthcare foodservice requires expertise, precision, and a deep understanding of regulatory standards. This is where Shinelong steps in. With over two decades of experience in creating tailored solutions for commercial kitchens, we specialize in optimizing layouts, selecting NSF-certified equipment, and integrating workflows that prioritize food safety and operational efficiency. Our team collaborates closely with hospitals, assisted living communities, and rehabilitation centers to deliver kitchens that align with HACCP protocols, minimize cross-contamination risks, and adapt to evolving needs, whether scaling for future growth or retrofitting existing spaces.

A testament to our commitment is the Myanmar-Grand Hantha International Hospital's Kitchen, where we designed centralized kitchens for nine healthcare facilities, ensuring seamless food delivery to hospital rooms while adhering to international hygiene benchmarks. From energy-efficient ventilation systems to allergen-segregated prep zones, the project showcased our ability to balance functionality with sustainability. Partner with us to turn your hospital kitchen vision into a reality—where innovation meets compliance, and patient well-being is always the priority!

-

What is a guide for designing a hospital kitchen?A step-by-step framework covering zoning, workflow, equipment selection, and safety protocols tailored to healthcare foodservice.

-

Which cooking utensil material is best for your health?304-grade stainless steel—it's non-reactive, durable, and easy to sanitize, making it ideal for healthcare kitchens.

-

How do hospitals cook patients' food?With specialized equipment such as combi ovens and sous-vide machines for precise temperature control and therapeutic diet consistency.

-

Can food be delivered to patients in hospitals?Yes—using insulated delivery carts or room-service systems that maintain safe temperature thresholds throughout transport.

-

What are the features of hospital kitchen equipment?Easy-to-clean surfaces, precise digital controls, built-in sanitation cycles, and NSF certification for healthcare-grade hygiene.

-

What kind of commercial kitchen equipment does a healthcare kitchen need?Core units include cooking range, combi ovens, induction cookers, chamber vacuum sealers, heated holding cabinets, and high-temperature dishwashers.

-

Do you keep cooking equipment stock?For the Furnotel elegant series, snack equipment, we usually keep stocks, it can be delivered within 10 days. Pls leave a message to ask for the stock list.

Since Shinelong was established in Guangzhou in 2008, we have made great strides in the fields of commercial kitchen planning and kitchen equipment manufacturing.

IF YOU HAVE ANY QUESTION,PLEASE CONTACT US.

WhatsApp: +8618902337180

WeChat: +8618924185248

Telephone: +8618924185248

Fax: +86 20 34709972

Email: info@chinashinelong.com

After-Sales Contact

Telephone: +8618998818517

Email: service@chinashinelong.com

Add: No. 1 Headquarters Center, Tian An Hi-tech Ecological Park, Panyu Avenue, Guangzhou, China.