SHINELONG Kitchen Equipment-A leading supplier of turnkey kitchen solutions in the hospitality and catering since 2008.

Shop Best Asian Commercial Kitchen Equipment in Shinelong

asian commercial kitchen equipment revitalizes Guangzhou Shinelong Kitchen Equipment Co., Ltd.. Here are some reasons that why it makes a great difference in the company. Firstly, it has a special appearance thanks to the industrious and knowledgeable designers. Its exquisite design and unique appearance have attracted many customers from the world. Secondly, it combines the wisdom of technicians and efforts of our staff. It is sophisticatedly processed and exquisitely made, thus making it be of extremely high performance. Lastly, it has a long service life and is of easy maintenance.

Customers make their purchase decision on the products under the brand Shinelong. The products excel others in reliable performance and high cost-effectiveness. Customers reap profits from the products. They return positive feedback online and tend to repurchase the products, which consolidates the image of our brand. Their trust in the brand brings more revenues to the company. The products come to stand for the brand image.

At SHIENLONG, we provide full service for samples. A strict and standardized sample production procedure has been established in advance. The excellent skills of our technicians enable us to provide our customers with the production of asian commercial kitchen equipment samples as well as the industry-standard production on a large scale.

Lighting is also an important factor in the design of restaurant kitchens, which is related to the lighting system of the entire kitchen and the convenience of staff operation. So, do restaurant kitchen operation room lamps need explosion-proof lamps? Are there any specific requirements? Today, SHINELONG editor will introduce whether restaurant kitchen operation room lamps need explosion-proof lamps. 1. There is open flame, non-explosion-proof area: Not necessary, the kitchen is well ventilated, all mechanical ventilation, as long as the lamps are waterproof. 2. Accidental ventilation after gas leakage, the fan centralized exhaust leads to a relatively high concentration of gas accumulation at the motor, so explosion-proof fans should be used for safety. There is no such requirement for equipment in other areas. Non-explosion hazardous areas include (1) areas where there is no release source and there is no possibility of flammable substances invading; (2) the highest concentration of flammable substances that may appear does not exceed 10% of the lower explosion limit; (3) near equipment that uses open flames in the production process, or near equipment where the surface temperature of hot parts exceeds the ignition temperature of flammable substances in the area; in recent years, kitchen gas explosion accidents have caused heavy losses. The state has mandatory regulations for gas stoves, and the gas must be turned off when the flame is turned off. In addition, adding a 220V explosion-proof sound and light alarm, interlocked with the closer, can also prevent such accidents from happening. Large gas leaks are generally caused by serious pipeline corrosion, the use of inferior pipes and stoves, and improper installation. Strengthening supervision and regular inspections can still avoid them. In summary: The above is some common sense about whether the restaurant kitchen operation room needs to install explosion-proof lights. For more information about restaurant kitchen projects, please follow the SHINELONG official website.

Understanding the hospital kitchen layout is crucial for operational efficiency, food safety, and meeting strict healthcare regulations. Unlike standard commercial kitchens, hospital foodservice facilities must integrate specialized workflows, rigorous hygiene protocols, and high-volume equipment to support diverse medical diets.

This article details the core elements defining a hospital kitchen, the governing design standards, key layout considerations, common configurations, and how professional solutions like those from Shinelong ensure optimal performance.

What Is a Hospital Kitchen?

A hospital kitchen definition is not just a food preparation area. It is the central kitchen department in hospital operations responsible for the safe, efficient, and nutritionally appropriate production of meals for patients, staff, and sometimes visitors. Its primary functions include:

-

Medical Nutrition Support: Serving as an integral component of hospital catering services, the kitchen is responsible for producing therapeutic diets tailored to individual patient needs as directed by clinical staff.

-

Mass Food Production: Serving large volumes of meals reliably within critical time windows.

-

Infection Control Hub: Implementing stringent hygiene protocols exceeding standard foodservice levels.

-

Logistics Management: Coordinating timely meal assembly, trayline operations, and ward distribution.

This facility requires specialized hospital food service equipment and workflows designed explicitly for the healthcare environment's demands.

Key Hospital Kitchen Design Standards

When it comes to designing a hospital kitchen, there are some key hospital kitchen design standards you must be aware of. These standards are stricter than those for normal commercial kitchens.

Healthcare-Specific Guidelines

The design and operation of hospital kitchens must comply with internationally recognized food safety and hygiene standards. Key global frameworks include:

-

World Health Organization (WHO) & Codex Alimentarius: Broad international standards for food hygiene, covering facility layout, personnel practices, and contamination prevention.

-

Hygienic Equipment Requirements:

-

1. Surfaces must be non-toxic, non-absorbent, and easy to clean.

-

2. Equipment should be constructed from corrosion-resistant materials, such as 304-grade stainless steel.

-

3. Surface finish must meet Ra ≤ 0.8μm to prevent microbial retention.

-

4. All joints and seams should be fully welded and free of gaps or crevices.

-

-

Thermal Sanitization Standards (for dishwashers and sanitation equipment):

-

1. Equipment must support validated heat-based disinfection cycles.

-

2. Integrated real-time temperature sensors are required to monitor and maintain sterilization thresholds.

-

3. Compliance should be verifiable through documented performance testing.

-

These standards ensure that the hospital kitchen layout, equipment, and processes align with the rigorous demands of healthcare foodservice, minimizing contamination risks and supporting patient safety.

Hospital Kitchen Layout Considerations

Optimizing a hospital kitchen layout involves balancing multiple critical factors:

-

Workflow Efficiency ("The Flow"): Implementing a strict unidirectional workflow (Receiving → Storage → Preparation → Cooking → Assembly → Distribution → Warewashing) is vital to prevent cross-contamination. This often defines the physical layout.

-

Zoning & Separation:

-

Dirty Areas: Receiving, bulk storage, vegetable prep, meat/fish prep, pot wash.

-

Clean Areas: Cooked food holding, tray assembly (ideally temperature-controlled), plating, clean ware storage.

-

Critical Control Areas: Dedicated spaces for special diet preparation with stricter access control and equipment.

-

-

Infection Control: Use of non-porous, seamless materials. Strategic placement of handwashing stations. Preferably separate entry and exit paths for staff, goods, and waste.

-

Equipment Selection & Placement: Hospital food service equipment must be durable, easy to sanitize, and certified. Common units include combi ovens, tilting pans, steamers, blast chillers, trayline systems, and high-temp dishwashers. Adequate utility infrastructure is essential.

-

Staff Safety & Ergonomics: Layout must reduce physical strain and allow safe, efficient movement.

-

Scalability & Flexibility: The kitchen must be adaptable to future operational changes or expansion needs.

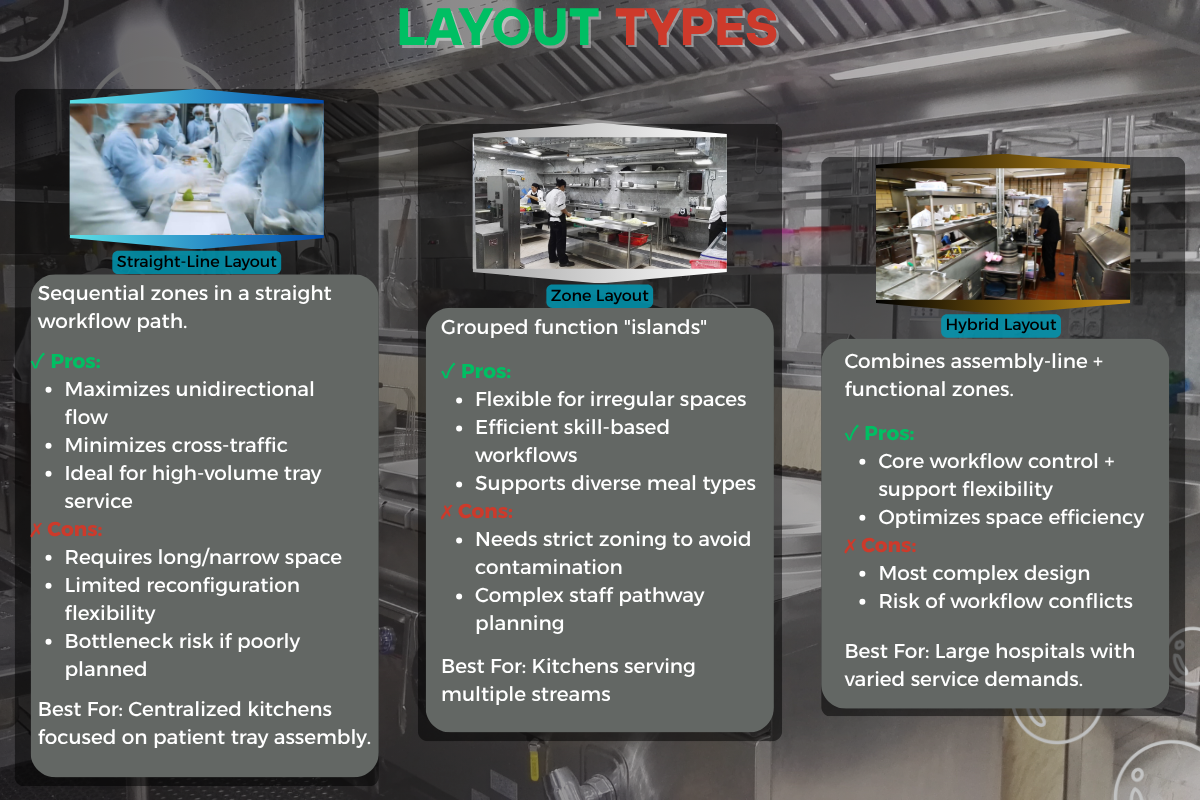

3 Common Hospital Kitchen Layout Types

Based on workflow principles and space constraints, three primary hospital kitchen layout configurations are prevalent:

How to Get a Professional Hospital Kitchen Solution with Shinelong

Designing and implementing a compliant, efficient, and safe hospital kitchen layout demands specialized expertise in kitchen solutions for hospitals. SHINELONG delivers an all-in-one kitchen solution through a structured approach:

1. Comprehensive Consultancy: Shinelong consultants collaborate closely with hospital administrators, clinical nutrition teams, and facilities managers to understand specific patient volumes, menu complexity (especially therapeutic diets), operational goals, budget, and existing space constraints.

With more than 20 years in the commercial kitchen industry, deep knowledge of hospital kitchen design standards and workflow efficiency, Shinelong creates optimized layouts. This includes:

Precise zoning and workflow mapping.

Detailed equipment schedules specifying appropriate hospital food service equipment.

Integration of critical infrastructure (HVAC, plumbing, electrical). Compliance validation against relevant codes (HACCP, NSF, local building/safety).

3. Equipment Specification & Manufacturing: Shinelong manufactures durable, high-performance, and easily sanitizable equipment from its own factory, ensuring it meets the specific demands of the kitchen department in hospital settings.

4. Project Management & Installation: Experienced project managers oversee the entire process, from demolition (if required) through to precise equipment installation, utility connec

5. Training & Handover: Shinelong provides thorough training for kitchen staff on the safe and efficient operation of new equipment and workflows within the optimized hospital kitchen layout.

6. After-sales support: Post-installation support ensures the kitchen operates at peak performance.

Ready to Set Up Your Hospital Food Service?

A well-designed hospital kitchen layout is fundamental to patient safety, staff efficiency, and nutritional care. Partnering with experts like Shinelong ensures your kitchen department in hospital operations meets the highest standards of hygiene, efficiency, and compliance. Contact SHINELONG today for a consultation on your kitchen solutions for hospitals project and discover how our expertise can construct your facility.

What Is a Chef?

A chef is a trained culinary professional responsible for designing menus, managing commercial kitchen operations, and maintaining food quality standards. In hotel kitchens, chefs rely on specialized hotel kitchen equipment and essential hotel tools to ensure every dish is prepared efficiently and consistently. They also play a crucial role in organizing hotel back of house storage, keeping workflows smooth between kitchen prep and service delivery. Their expertise directly impacts guest satisfaction, cost control, and brand reputation, making them indispensable in rigid hospitality environments.

Chef Ranks in Hotel Kitchens

Hotel kitchens operate under a strict hierarchy. This system clarifies responsibilities and streamlines workflows in high-pressure commercial kitchen equipment-heavy environments. Below is a simplified overview of key roles:

Our in-house designers and engineers have produced countless great designs for customers from different industries

Key Types of Chefs in Hotels

The efficiency of a hotel kitchen relies on specialized roles. Each chef masters a specific domain, operating commercial-grade equipment, executing meticulous ingredient prep, perfecting niche cooking techniques, or ensuring spotless plate presentation—so the entire station fires on all cylinders and the guest experience remains flawless.

Executive Chef

The Executive Chef sits at the top of the kitchen hierarchy—think of them as the head coach. From shaping menus to managing budgets, they oversee every aspect of the kitchen in a hotel, making sure the team, the workflow, and all hotel kitchen equipment are running like clockwork. It’s a role that blends leadership, creativity, and sharp business sense.

Sous Chef

Right under the Executive Chef, the Sous Chef is the one keeping things under control when service hits full speed. In a busy hotel foodservice operation, they juggle schedules, coordinate plating, and make sure prep stations don’t miss a beat. Whether it’s a fryer acting up or a timing issue, they’re the first to jump in.

Station Chef

Station Chefs focus on mastering one area—be it grill, fry, or fish—and the tools that come with it. In a 5 star hotel kitchen design, everything from their workstation to hotel back of house storage is set up for precision, speed, and cleanliness. It’s a hands-on role, ideal for chefs who thrive on consistency and detail.

Saucier

The Sauté Chef crafts sauces, sautés, and reductions—key to elevating dishes like risottos and pan-seared meats. In a kitchen for hotel, they rely on precise food preparation equipment to maintain flavor consistency and control heat.

Garde Manger

The Pastry Chef prepares cold dishes like salads, terrines, and buffet spreads. In star rated hotels, they use specialized hotel kitchen equipment to ensure both efficiency and food safety.

Friturier

The Fry Chef handles deep frying and crisp textures, using catering fryers or open fryers designed for a enormous amount of foodservice. They regularly check oil quality and stay alert to avoid safety risks during fast-paced service.

Poissonnier

Specializing in seafood, the Poissonnier ensures freshness, proper prep, and delicate cooking techniques. In many hotels, they manage cold chain logistics and utilize designated hotel back of house storage for raw fish.

Grillardin

Focused on proteins like steaks and chops, the Grill Chef works over integrated stove or griller. In hotel foodservice, timing is everything—overcooking premium cuts can mean wasted product and disappointed guests.

Entremetier

This role covers vegetables, eggs, and light starters. Knife skills, timing, and seasonal creativity are key—especially when working with rotating menus in a kitchen in a hotel.

Expediter

The Expediter acts as the bridge between back-of-house and front-of-house, keeping the kitchen in sync. They relay orders between servers and stations with laser-focused timing—critical in luxury hotel dining, where guest experience is everything. Even a five-second delay can shatter the service rhythm.

Prep Cook

Prep Cooks handle the groundwork—peeling, chopping, portioning, and prepping mise en place. They maintain tools like processors and blenders as part of daily hotel kitchen maintenance, keeping stations ready for action.

Conclusion

Every station in a hotel kitchen functions like a gear in a finely tuned clock—precise, essential, and interdependent. The kitchen crew operates like a disciplined military unit: there is rank, there is order, and there is no room for miscommunication. In hotel foodservice, it’s not just cooking—it’s combat. Time, coordination, and execution are everything. Victory isn’t just a plate served—it’s a system running perfectly under pressure.

Hotel Case Studies

Are you planning to set up a hotel kitchen, Shinelong has got you covered. More importantly, our after - sales service includes spare parts supply and maintenance, ensuring the long - term smooth operation of your kitchen.

ACHIEVEMENTS

Commercial stove top grills have come a long way in recent years, with innovative technologies and trends shaping the future of cooking in commercial kitchens. From sleek designs to advanced features, these grills are changing the way chefs prepare meals, making cooking faster, easier, and more efficient. In this article, we will explore the latest innovations and trends in commercial stove top grills that are revolutionizing the culinary world.

The Rise of Induction Technology

Induction technology has been taking the culinary world by storm, and it is no surprise that it is making its way into commercial stove top grills. Induction technology uses electromagnetic energy to heat the cookware directly, rather than the surface of the grill. This results in faster cooking times, more precise temperature control, and energy efficiency. Chefs can now sear meats, sauté vegetables, and grill seafood with precision and consistency. Induction technology also allows for easy cleanup, as the surface of the grill remains cool to the touch. With the rise of induction technology, commercial stove top grills are becoming an essential tool in professional kitchens.

Sleek and Modern Designs

Gone are the days of clunky, unattractive commercial stove top grills. Today, manufacturers are focusing on sleek and modern designs that not only look great but also improve functionality. From stainless steel finishes to glass cooktops, commercial stove top grills are now a stylish addition to any kitchen. These modern designs are not just for show – they also enhance the cooking experience. Features such as touch controls, LED displays, and programmable settings make it easier than ever for chefs to create delicious dishes with precision and flair. With sleek and modern designs, commercial stove top grills are as much a statement piece as they are a cooking tool.

Smart Technology Integration

Smart technology is revolutionizing the way we cook, and commercial stove top grills are no exception. Manufacturers are integrating smart technology into their grills, allowing chefs to control the cooking process from their smartphones or tablets. This means chefs can monitor temperatures, set timers, and receive notifications all from the palm of their hand. Smart technology also enables chefs to access recipes, cooking tips, and tutorials, making it easier than ever to create gourmet meals. With smart technology integration, commercial stove top grills are becoming more user-friendly and efficient than ever before.

Enhanced Safety Features

Safety is a top priority in commercial kitchens, and manufacturers are incorporating enhanced safety features into their stove top grills. From automatic shut-off functions to overheating protection, these features help prevent accidents and ensure a safe cooking environment. Some commercial stove top grills also come with child lock settings, preventing unauthorized use and providing peace of mind. These enhanced safety features not only protect chefs and kitchen staff but also contribute to a more efficient and productive kitchen.

Environmental Sustainability

As awareness of environmental issues grows, so does the demand for environmentally sustainable products. Manufacturers of commercial stove top grills are responding to this demand by creating products that are eco-friendly and energy-efficient. Many grills now come with energy-saving modes, which reduce electricity consumption and carbon emissions. Some grills are also made from recycled materials, further reducing their environmental impact. By choosing environmentally sustainable commercial stove top grills, chefs can not only cook with a clear conscience but also contribute to a greener future for the planet.

In conclusion, the future of commercial stove top grills is filled with exciting innovations and trends that are shaping the way we cook. From induction technology to smart technology integration, sleek designs to enhanced safety features, these grills are becoming more advanced and user-friendly than ever before. Chefs can now create gourmet meals with precision and ease, all while reducing their environmental impact and maintaining a safe cooking environment. With the latest trends in commercial stove top grills, the culinary world is sure to be transformed for the better.

Whether you are setting up a new commercial kitchen or looking to upgrade your current setup, deciding between a commercial electric salamander and a griddle can be a tough choice. Both of these pieces of equipment are essential for any professional kitchen, but they serve different purposes and have unique features. In this article, we will break down the differences between a commercial electric salamander and a griddle and help you determine when to choose one over the other.

Commercial Electric Salamander

A commercial electric salamander is a versatile piece of equipment that is commonly used in professional kitchens for tasks like broiling, toasting, browning, and melting cheese. It consists of a heating element located on the top of the unit that emits radiant heat, similar to a broiler. The heat source can be adjusted to different levels depending on the cooking requirements.

One of the main advantages of a commercial electric salamander is its ability to cook food quickly and evenly. The radiant heat produced by the unit ensures that food is cooked thoroughly from the top, resulting in a crispy and caramelized exterior while keeping the inside tender and juicy. This makes it an excellent option for finishing dishes or adding a golden crust to dishes like casseroles, gratins, or desserts.

Another benefit of a commercial electric salamander is its compact size and versatility. It can be easily mounted on a wall or installed above a range, freeing up valuable countertop space in the kitchen. Additionally, many models come with adjustable racks or shelves that allow you to control the distance between the food and the heat source, giving you more control over the cooking process.

In terms of cleaning and maintenance, commercial electric salamanders are relatively easy to clean. Most units come with removable crumb trays or drip trays that catch food debris and grease, making it simple to keep the unit clean and hygienic. Regular cleaning and maintenance of the heating element will ensure that your salamander remains in top condition and performs efficiently.

While a commercial electric salamander offers several advantages, there are also some limitations to consider. One drawback is that the heat source is concentrated on the top of the unit, which means that it may not be suitable for cooking large quantities of food or items that require cooking on both sides simultaneously. Additionally, the radiant heat can be intense, so it is important to monitor the cooking process closely to prevent burning or overcooking.

Overall, a commercial electric salamander is a valuable addition to any professional kitchen, especially if you need a versatile piece of equipment for broiling, toasting, or finishing dishes. Its compact size, quick cooking capabilities, and ease of use make it a popular choice for many chefs and cooks.

Griddle

A griddle is a flat cooking surface that is used to cook a variety of foods, such as pancakes, eggs, burgers, and vegetables. It can be heated using gas, electricity, or steam and typically comes in different sizes to accommodate various cooking needs. Griddles are popular in commercial kitchens, as they offer a large cooking surface that allows for high-volume cooking and consistent results.

One of the main advantages of a griddle is its versatility and ability to cook a wide range of foods. The flat cooking surface provides an even heat distribution, ensuring that food is cooked uniformly without hot spots or uneven cooking. This makes it ideal for preparing breakfast items like bacon and eggs, lunch items like burgers and sandwiches, or dinner items like grilled vegetables or seafood.

Another benefit of a griddle is its efficiency and speed. The large cooking surface allows you to cook multiple items at once, saving time and increasing productivity in the kitchen. Additionally, many griddles come with temperature controls that allow you to adjust the heat settings to suit different types of food, ensuring that each dish is cooked to perfection.

In terms of maintenance, griddles are relatively easy to clean and maintain. Most models come with removable grease traps or drip trays that collect excess oil and grease, making it simple to keep the cooking surface clean and free from debris. Regular cleaning and seasoning of the griddle surface will help prevent food from sticking and ensure that your griddle remains in good condition.

While a griddle offers many benefits, there are also some drawbacks to consider. One limitation is that a griddle may not be suitable for certain types of cooking techniques, such as broiling or toasting, which require a direct heat source from above. Additionally, griddles can take up a significant amount of space in the kitchen, so it is important to consider the available countertop or floor space before investing in a griddle.

Overall, a griddle is a versatile and efficient piece of equipment that is well-suited for high-volume cooking and a wide range of food items. Its large cooking surface, even heat distribution, and ease of use make it a popular choice for many commercial kitchens looking to increase productivity and prepare delicious dishes consistently.

When to Choose a Commercial Electric Salamander

There are certain situations where choosing a commercial electric salamander over a griddle makes sense. One of the main reasons to opt for a salamander is when you need to finish or brown dishes quickly and achieve a caramelized crust on top. Salamanders are excellent for tasks like melting cheese, toasting bread crumbs, or browning gratin dishes, as they provide an intense and direct heat source from above.

Another scenario where a commercial electric salamander is the better choice is when you have limited space in the kitchen. Salamanders are typically compact in size and can be mounted on a wall or installed above a range, making them ideal for kitchens with limited countertop space. This allows you to maximize the available workspace and still have access to a versatile cooking tool.

Additionally, if you frequently prepare dishes that require broiling, grilling, or toasting, a commercial electric salamander is a valuable addition to your kitchen. Its quick heating capabilities and adjustable heat settings make it easy to achieve the desired level of browning or doneness on a wide range of food items, making it a versatile and efficient cooking tool.

When to Choose a Griddle

On the other hand, there are times when choosing a griddle over a commercial electric salamander is the more practical option. If you need to cook large quantities of food at once or prepare a variety of dishes that require a flat cooking surface, a griddle is the ideal choice. Its large cooking surface and even heat distribution make it suitable for cooking multiple items simultaneously without sacrificing quality.

Another situation where a griddle is the better option is when you need to cook items that require flipping or turning during the cooking process. Griddles provide a consistent and uniform heat source across the entire cooking surface, allowing you to cook food evenly on both sides without the need for constant monitoring. This is especially useful when preparing items like pancakes, burgers, or grilled vegetables.

Additionally, if you are looking to increase productivity and efficiency in the kitchen, a griddle is a valuable investment. Its large cooking surface and quick heating capabilities allow you to cook food quickly and consistently, saving time and effort during busy service hours. Whether you are preparing breakfast items, lunch specials, or dinner entrees, a griddle can help you streamline the cooking process and deliver delicious dishes to your customers.

In conclusion, choosing between a commercial electric salamander and a griddle depends on your specific cooking needs, space constraints, and menu requirements. Both pieces of equipment offer unique features and benefits that can enhance the efficiency and productivity of your kitchen. Consider the type of dishes you will be preparing, the volume of food you will be cooking, and the available space in your kitchen before making a decision. Whether you choose a commercial electric salamander for broiling and finishing dishes or a griddle for high-volume cooking and versatility, both options will help you create delicious meals and satisfy your customers' cravings.

Since SHINELONG was established in Guangzhou in 2008, we have made great strides in the fields of commercial kitchen planning and kitchen equipment manufacturing.

IF YOU HAVE ANY QUESTION,PLEASE CONTACT US.

WhatsApp: +8618902337180

WeChat: +8618924185248

Telephone: 20-34709971

Fax: +86 20 34709972

Email: info@chinashinelong.com

After-Sales Contact

Whatsapp :+8619195343796

Email: service@chinashinelong.com

Add: No. 1 Headquarters Center, Tian An Hi-tech Ecological Park, Panyu Avenue, Guangzhou, China.