SHINELONG Kitchen Equipment-A leading supplier of turnkey kitchen solutions in the hospitality and catering since 2008.

The best commercial kitchen equipment tops the product category of Guangzhou Shinelong Kitchen Equipment Co., Ltd.. All its raw materials are strictly selected and then are put into precision production. The standard production process, advanced production technique, and systematic quality control together guarantee the high quality and excellent performance of the finished product. Thanks to the continued market survey and analysis, its positioning and application scope are being clearer.

We believe the exhibition is a rather effective brand promotion tool. Before the exhibition, we usually do research first about questions like what products customers expect to see on the exhibition, what customers care most, and so on in order to get ourselves fully prepared, thus to effectively promote our brand or products. In the exhibition, we bring our new product vision to life through hands-on product demos and attentive sales reps, to help capture attention and interests from customers. We always take these approaches in every exhibition and it really works. Our brand - Shinelong now enjoys greater market recognition.

We dedicate ourselves into diversifying and optimizing the service. Not only we offer customers service to satisfy needs of different customers, but we guarantee the shipping service totally safe and reliable. Moreover, the shipping method of the products including best commercial kitchen equipment is also customizable at SHIENLONG.

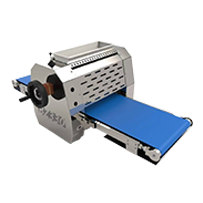

I believe you've definitely struggled with these issues when running a bakery or pastry shop. Sometimes the dough ends up being inconsistent—either too thin, too thick, or unevenly rolled. That's why a commercial dough sheeter is so indispensable in professional bakeries and high-volume kitchens. Designed to replace labor-intensive hand-rolling, this machine transforms dough balls into uniformly thin sheets—perfect for pastries, thin-crust pizzas, croissants, and laminated doughs. Unlike basic dough rollers, which focus on speed, dough sheeters prioritize precision, offering adjustable thickness settings (often as fine as 1mm) to ensure consistent results and maintain a high standard in commercial bakery kitchens.

Built with stainless steel rollers and heavy-duty motors, these machines handle everything from delicate gluten-free dough to sticky sourdough without tearing, making them essential for both artisanal bakeries and large-scale operations.

As an essential bakery equipment, countertop dough sheeters are compact, portable, and ideal for small bakeries or cafes with limited space. They typically process 10–15kg of dough per hour, perfect for boutique croissants or weekly pastry batches. In contrast, industrial floor models dominate commercial kitchens, boasting widths up to 520mm and capacities exceeding 50kg/hour. These giants are built for high-output tasks like mass-producing frozen pizza bases or puff pastry sheets.

Manual sheeters require operators to feed dough by hand, offering granular control for specialty items like phyllo or gluten-free crusts. Automatic models, equipped with conveyor belts, streamline repetitive tasks—ideal for 24/7 bakeries or chains prioritizing speed. For example, a croissant factory might use automatic sheeters to maintain consistent layering during peak production.

The magic lies in its roller system. Dough is fed between two rotating cylinders, which press and stretch it into a sheet. Thickness is adjusted via dials or digital controls, while scrapers prevent sticking. Advanced models include reverse functions to correct uneven edges. Actually, automatic models are equipped with conveyor belts that streamline the feeding process, making them incredibly popular in the baking industry. This not only increases efficiency but also ensures that the dough is evenly rolled without manual intervention. For laminated doughs, some sheeters integrate chilling systems to keep butter layers intact, critical for achieving the flaky texture of croissants.

When you go to buy a dough sheeter for your baking business, you might find a very similar machine: the dough roller. I bet that can definitely be confusing. So in this part, I'll show you the key differences between the two. A dough roller prioritizes speed over precision. Unlike dough sheeters, which meticulously control thickness through adjustable rollers, dough rollers use fixed cylinders to flatten dough quickly. This makes them perfect for rustic breads, pie crusts, or bulk pizza bases, where minor inconsistencies don't impact quality. These machines thrive in high-volume bakeries or pizzerias that churn out hundreds of rolls daily, sacrificing exactness for raw efficiency.

Laminated doughs: A dough sheeter's adjustable rollers create precise, paper-thin layers essential for croissants and puff pastry. By automating the folding process, it achieves 27+ butter layers without manual labor—critical for French patisseries aiming for flaky perfection.

Phyllo or strudel: Delicate doughs like phyllo demand sub-millimeter accuracy. Commercial sheeters gently stretch dough to 0.2mm thickness without tearing, a feat impossible with hand-rolling or basic rollers, ensuring crisp baklava or apple strudel every time.

Gluten-free baking: Gluten-free doughs crumble under harsh handling. Sheeters apply controlled pressure to maintain structure, preventing dense textures in sensitive recipes like almond flour tart shells or vegan puff pastry.

Automated Efficiency: Modern sheeters integrate timers and preset programs, allowing bakers to multitask. For example, a bakery can simultaneously sheet croissant dough while filling éclairs, slashing prep time by up to 40%.

Match dough hydration to machine settings: Sticky doughs require slower roller speeds to avoid tearing.

Clean daily: Wipe flour residue with a soft brush; never hose down electrical components.

Lubricate weekly: Apply food-grade oil to gears and bearings to prevent wear.

Imagine a thriving hotel kitchen during peak breakfast service: chefs juggling island stations, servers darting in for fresh coffee carafes, and a line cook frantically searching for the backup bin of pancake mix. In this chaos, every second counts—and the difference between smooth service and costly delays often comes down to one critical factor: how the kitchen stores its ingredients, tools, and equipment.

For hotels, where reputation largely hinges on consistent quality and timely service, a poorly designed storage system is not merely inconvenient; it is a liability. Let's analyze what truly makes a commercial kitchen storage solution effective, why it is non-negotiable for modern hotels, and how to establish a smooth and comprehensive storage system.

Before discussing kitchen storage solutions, it's worth understanding why storage is an essential element in hotel kitchens. Unlike residential spaces, hotel kitchens operate at a commercial scale. They are tasked with:

• Storing enough ingredients to serve hundreds (or thousands) of guests daily.

• Preventing cross-contamination between raw and cooked foods.

• Complying with strict health department regulations.

• Minimizing waste in an industry where profit margins are narrow.

Consider this: A study by the American Hotel & Lodging Association found that hotels waste 12-15% of their food inventory annually due to improper storage, resulting in thousands of dollars lost per property. Furthermore, disorganized kitchens increase the risk of health code violations, which can lead to fines or even temporary closures.

The best hotel kitchens function like precision instruments, and their storage systems are no exception. Here's what a well-designed setup looks like in practice:

Stainless steel isn't just a buzzword—it's the backbone of any hygienic kitchen. Unlike wood or plastic, it resists bacterial growth, withstands daily sanitization, and lasts for decades.

Key Applications:

• Adjustable shelving units: These allow the hotel kitchen to customize vertical space for everything from giant sacks of flour to delicate pastry trays. Tip: Leave a 6-inch gap between shelves and walls for proper air circulation.

• Mobile prep tables with under-counter storage: These are practical for banquet kitchens, allowing staff to prepare salads on one side while storing serving platters underneath.

• Lockable cabinets for high-risk items: Reserve these for allergens like nuts or premium ingredients like truffle oil.

Hotels need to store everything from fresh herbs to frozen puff pastry—often in the same kitchen. This requires a tiered approach:

• Walk-in coolers: Opt for models with separate zones for dairy (34°F), produce (38°F), and raw meat (32°F). Glass-front doors help staff quickly locate items without wasting cold air.

• Blast chillers: Critical for large hotels that prep meals in advance. These rapidly cool hot foods to safe temperatures, extending shelf life by up to 72 hours.

• Dry storage rooms: Maintain these at 50-70°F with <15% humidity. Use airtight storage bins labeled with expiry dates—color-coding by day of the week simplifies FIFO (First In, First Out) rotation.

• Containerized Cold Rooms: Modular cold rooms, often built with stainless steel panels and insulated cores, offer scalable solutions for hotels with fluctuating storage needs. These units can be customized with separate zones, such as dedicated meat lockers (maintained at 28–32°F) to prevent bacterial growth or produce chambers (36–40°F) with humidity controls to extend the freshness of leafy greens by up to 50%.

Even the fanciest storage system fails if staff don't use it properly. Smart hotels design around their team's workflow:

• Place high-use items at eye level: Your line cooks shouldn't bend or stretch for olive oil or salt.

• Install magnetic knife strips near prep stations: Saves counter space and reduces accidents from cluttered drawers.

• Use translucent bins for backups: Staff can see when the pancake mix is running low without opening every container.

Artificial intelligence is quietly revolutionizing how hotels manage stock—minimizing waste and streamlining orders.

• Automated Shelf-Life Tracking: Smart labels with QR codes now sync with inventory software, automatically updating expiry dates. Staff scans items during prep, and the system prioritizes usage—critical for compliance with HACCP standards.

Consider the example of Hotel Miramar in Barcelona. After redesigning their kitchen storage with expert guidance, they achieved measurable results within months:

• A 22% reduction in food waste, saving €18,000 annually.

• 15% faster service times during peak hours.

• Zero health code violations for two consecutive years.

These results are not isolated. Hotels that prioritize storage efficiency typically report:

• 30% fewer inventory errors.

• Extended equipment lifespan due to proper storage.

• An effective storage solution ensures that the hotel's food remains fresh.

A hotel's kitchen storage system isn't just about shelves and bins—it's about establishing an ecosystem where food stays fresh, staff work efficiently, and costs are controlled. Whether you're building a new property or optimizing an existing kitchen, start by auditing your current pain points.

While some hotels try to piece together storage solutions from generic suppliers, industry leaders work with specialists who understand the unique demands of hospitality. For example, Shinelong Commercial Kitchens, a global supplier with over 20 years of experience in hotel projects, can help hotel businesses build a modern and efficient kitchen storage system or even a complete hotel kitchen solution. Our service's key advantage is the use of 3D modeling to design storage systems that:

• Align with your menu and service style

• Integrate with existing equipment, such as combi ovens or dishwashers

• Meet local health codes (NSF, CE, or HACCP certifications)

Our modular stainless steel units are particularly popular for star-rated hotel projects, as they can transform limited spaces (like under staircases) into functional storage. As the effectiveness of your service and the satisfaction of your customers grow increasingly vital in the hotel business, every square inch of your kitchen should be working to support this mission. Isn't it time your storage system pulled its weight?

Why are stainless steel kitchen utensils and equipment commonly used in commercial kitchens? This is because stainless steel is widely used in commercial kitchen equipment, with its unique performance advantages and significant cost-effectiveness. The following are the main features and advantages of stainless steel materials in commercial kitchen equipment summarized by Shinelong for you: 1. Strong corrosion resistance Stainless steel has excellent corrosion resistance and can resist the erosion of common corrosive substances such as acids, alkalis, and salts in the kitchen environment. This makes stainless steel equipment less likely to rust during long-term use, keeping the equipment neat and beautiful. 2. Good high temperature resistance Commercial kitchen equipment often needs to withstand the test of high-temperature cooking, and stainless steel materials have good high temperature resistance. It can maintain stable physical and chemical properties at high temperatures, is not easy to deform or damage, and ensures the long-term stable operation of the equipment. 3. Easy to clean The surface of stainless steel is smooth and not easy to be contaminated with oil and bacteria. This makes stainless steel equipment very convenient to clean. Just wipe it with clean water or a mild detergent to restore the surface to a bright and new one. This is essential for maintaining kitchen hygiene and food safety. 4. Beautiful and durable Stainless steel has a bright color and a sense of modernity and technology. At the same time, it is also wear-resistant and scratch-resistant, and can maintain its beauty after long-term use. This makes stainless steel equipment one of the indispensable decorative elements in commercial kitchens. 5. Environmentally friendly and healthy Stainless steel materials are non-toxic and tasteless, and will not pollute food. It meets national and local food safety standards and is one of the ideal material choices for commercial kitchen equipment. 6. Application examples In commercial kitchens, stainless steel materials are widely used in the manufacture of various equipment, including but not limited to: Stove: Stainless steel stove racks and burners can withstand high temperatures and remain stable. Ovens and steam cabinets: The inner and outer shells are made of stainless steel, which is corrosion-resistant and easy to clean. Workbench, sink: The stainless steel workbench and sink have smooth surfaces, are easy to clean, and can resist corrosive substances in the kitchen. Refrigeration and freezing equipment: The outer shell and inner tank are made of stainless steel to ensure the durability and hygiene of the equipment. Storage cabinets and shelves: Stainless steel storage cabinets and shelves can withstand heavy objects and remain tidy. In summary, stainless steel occupies an important position in commercial kitchen equipment due to its strong corrosion resistance, good high temperature resistance, easy cleaning, beautiful and durable, and environmentally friendly and healthy characteristics. Keywords: Guangzhou kitchenware factory, Guangzhou stainless steel kitchenware.

Author:SHINELONG-Commercial Kitchen Equipment Solutions Suppliers

Innovations in self-cleaning functions for commercial kitchen equipment

Commercial kitchens are known for being hotspots of culinary creativity and chaotic cooking. They are fast-paced environments where chefs and cooks work tirelessly to prepare delicious meals for their customers. However, one aspect of these bustling kitchens often gets overlooked - the cleaning process. Cleaning commercial kitchen equipment is a time-consuming and labor-intensive task that can take away precious minutes from the cooking process. Luckily, advancements in technology have given rise to innovative self-cleaning functions for commercial kitchen equipment, making the cleaning process more efficient and hassle-free. In this article, we will explore some of the latest innovations in self-cleaning functions for commercial kitchen equipment.

Innovative Technology for Efficient Cleaning

Cleaning commercial kitchen equipment can be a daunting task, especially when there is a long list of equipment that requires regular maintenance. However, thanks to innovative technology, self-cleaning functions have emerged as a game-changer. These functions use advanced mechanisms and smart algorithms to automate the cleaning process, reducing the manual effort required.

One such innovation is the use of sensors in kitchen equipment. These sensors are designed to detect dirt, grease, and other contaminants, triggering the self-cleaning function. For example, modern ovens are equipped with sensors that detect food spills or grease build-up. Once detected, the oven initiates a self-cleaning cycle, using heat to burn off the residues and leaving the oven clean and ready for the next use. This not only saves time and effort but also ensures a hygienic cooking environment.

Another interesting innovation is the integration of self-cleaning functions in dishwashers. Traditional dishwashers require manual pre-rinsing of dishes before loading them into the machine. However, with the advent of self-cleaning dishwashers, this pre-rinsing step is no longer necessary. These dishwashers are equipped with powerful jets and sprayers that can remove even stubborn food particles without any pre-rinsing. This not only saves time but also conserves water, making it an eco-friendly option for commercial kitchens.

Hygiene and Safety

Maintaining proper hygiene and safety standards is paramount in commercial kitchens. Self-cleaning functions play a significant role in maintaining a clean and safe environment for food preparation. By automating the cleaning process, these functions eliminate the risk of human error or oversight, reducing the chances of contamination.

Commercial deep fryers are notorious for their accumulation of oil and grease. Cleaning them manually can be a laborious task, often involving heavy scrubbing and the use of harsh chemicals. However, with the introduction of self-cleaning deep fryers, this process has become more streamlined. These fryers are equipped with automatic filtration systems that remove the impurities and debris from the oil, ensuring longer oil life and maintaining the quality of fried food. This not only saves time but also reduces the health hazards associated with improper cleaning of deep fryers.

Sustainability and Energy Efficiency

In addition to making the cleaning process more convenient, self-cleaning functions also contribute to sustainability and energy efficiency in commercial kitchens. By automating the cleaning process, these functions eliminate the need for excessive water usage and the use of harsh chemicals, reducing the environmental impact.

Self-cleaning grills and griddles have gained popularity in commercial kitchens due to their sustainability benefits. Traditional grill cleaning involves scraping off the burnt food residues manually, which often requires the use of excessive water and cleaning agents. However, self-cleaning grills have a built-in system that heats the grill surface to high temperatures, effectively burning off the food residues. This not only saves water but also reduces the reliance on chemical cleaning agents, making it an eco-friendly option for commercial kitchens.

Ease of Use

Apart from their cleaning capabilities, self-cleaning functions also enhance the overall user experience in commercial kitchens. These functions are designed to be user-friendly and intuitive, making them easily accessible for kitchen staff.

One example of user-friendly self-cleaning functions is found in combi-ovens. Combi-ovens are versatile cooking appliances that combine the functionalities of a convection oven and a steam oven. They are widely used in commercial kitchens for their ability to cook a variety of dishes. Modern combi-ovens come with self-cleaning functions that simplify the cleaning process. These functions provide step-by-step cleaning instructions and guide the user through each cleaning cycle. With just a few taps on the control panel, the combi-oven takes care of the rest, ensuring a clean and ready-to-use appliance.

Summary

Innovation in self-cleaning functions for commercial kitchen equipment has revolutionized the way cleaning is approached in these fast-paced culinary environments. From sensors that detect dirt and initiate cleaning cycles to automatic filtration systems that maintain the quality of oils, these functions have significantly reduced the manual effort required for cleaning. They also contribute to maintaining hygiene and safety standards, while promoting sustainability and energy efficiency. With their user-friendly interfaces and intuitive operations, these self-cleaning functions have become a valuable addition to commercial kitchens, ensuring a clean and efficient cooking environment. So, the next time you step into a bustling restaurant, take a moment to appreciate the behind-the-scenes innovation that keeps the kitchen sparkling clean.

.Recommand:

From artisan bakeries to high-end patisseries, the bakery industry has taken the world by storm. At its core, a bakery is defined as a place where baked goods—such as bread, pastries, and cakes—are produced and sold. The concept of baking dates back thousands of years to ancient Egypt, where early forms of bread were baked in clay ovens. Over the centuries, the craft of baking spread across the globe, evolving into a diverse and dynamic industry with countless business models.

Today, bakeries play a significant role in both retail and commercial foodservice sectors. With the rapid advancement of bakery equipment and kitchen design, modern bakeries have become more efficient, consistent, and scalable than ever before—empowering bakers to meet growing demands while maintaining quality and creativity.

Bakeries are more than just food providers—they are cultural fixtures and sources of daily comfort. Different bakery types serve various roles, from neighborhood shops baking bread every morning to artisan patisseries crafting desserts for special occasions. The act of producing freshly baked goods is often considered an art form, blending tradition with skill.

Whether it’s a warm croissant with morning coffee or a customized cake for a birthday, bakeries create moments of joy and nostalgia. In many communities, a local bakery is a meeting place, a morning ritual, and a place of celebration. From simple loaves to gourmet treats, they deliver more than food—they deliver emotion, identity, and heritage.

Retail bakeries are perhaps the most recognizable type of bakery globally. These are storefront operations selling directly to consumers, offering a wide range of types of bakery pastries including croissants, muffins, doughnuts, and artisan bread. Often, they double as cafes where customers enjoy their purchases on-site. This type of bakery is common in both urban and suburban areas, serving daily needs with freshly made offerings.

Commercial or wholesale bakeries operate on a larger scale, supplying supermarkets, restaurants, and hotels. Their focus is on volume and consistency, using industrial bakery equipment and optimized production lines. These bakeries usually feature automated processes to handle massive orders and a wider range of products. As part of the broader bakery industry, they play a critical role in maintaining supply chains for types of pastries in a bakery setup.

In China, traditional bakeries offer unique regional specialties such as egg tarts, wife cakes, and pineapple cakes. These products reflect local tastes and culinary heritage. Chinese-style bakeries often blend Western techniques with Asian flavors, creating distinctive types of bakery pastries that stand out in the global bakery industry. These bakeries not only cater to local demands but have also begun to influence bakery trends internationally.

Historically, bakery kitchens relied on manual tools—stone ovens, wooden paddles, and hand mixers. The equipment layout was simple, often centered around a single oven and preparation bench. Efficiency was driven by the skill of the baker rather than machinery.

Today’s bakery kitchen is a showcase of innovation. Modern commercial kitchen setups feature automated bakery equipment such as dough sheeters, planetary mixers, and deck ovens. These machines reduce manual labor while increasing consistency and productivity. An optimized bakery equipment layout ensures a smooth workflow, minimizes waste, and enhances sanitation.

For large-scale production, bakery conveyor belts and integrated automation systems have become essential. These technologies are crucial for high-volume operations such as factory-based commercial bakeries. Equipment like rotary ovens, spiral mixers, and proofing cabinets streamline the baking process, helping businesses scale without sacrificing quality or flavor.

Globally recognized baked goods include staples like baguettes, sourdough, croissants, and brownies. These items dominate bakery menus across continents and appeal to a wide range of tastes. They form the foundation of many types of bakery pastries, and their popularity supports a robust global bakery industry.

In commercial kitchens, the focus often turns to items with longer shelf life and mass appeal—such as sandwich loaves, burger buns, danishes, and sheet cakes. These types of pastries in a bakery are produced in bulk using standardized recipes, ensuring consistent flavor and appearance for restaurants, cafeterias, and hotels.

Chinese bakeries feature a range of beloved local pastries. Egg tarts with flaky crusts, wife cakes filled with winter melon, and pineapple cakes wrapped in buttery pastry are just a few examples. These distinctive types of bakery pastries reflect cultural heritage and are increasingly entering the mainstream of the global bakery industry.

Over the next three to five years, the bakery industry will continue evolving with rising demand for health-focused recipes, plant-based options, and gluten-free alternatives. Meanwhile, bakery kitchens are embracing smart ovens, touch-screen controls, and energy-efficient designs.

Automation is revolutionizing high-volume commercial kitchen operations. Modular bakery equipment layouts now enable flexible production and fast adaptation to changing trends. Smart baking systems will soon monitor humidity, heat, and timing in real-time to ensure precision and consistency.

As innovation accelerates, suppliers like Shinelong Kitchen are leading the way. With deep expertise in bakery equipment and commercial kitchen planning, Shinelong provides turnkey solutions that help businesses create modern, scalable bakery operations. For any professional looking to upgrade or build a bakery kitchen, choosing the right bakery equipment supplier is key to future growth.

Since SHINELONG was established in Guangzhou in 2008, we have made great strides in the fields of commercial kitchen planning and kitchen equipment manufacturing.

IF YOU HAVE ANY QUESTION,PLEASE CONTACT US.

WhatsApp: +8618902337180

WeChat: +8618924185248

Telephone: 20-34709971

Fax: +86 20 34709972

Email: info@chinashinelong.com

After-Sales Contact

Whatsapp :+8619195343796

Email: service@chinashinelong.com

Add: No. 1 Headquarters Center, Tian An Hi-tech Ecological Park, Panyu Avenue, Guangzhou, China.