I believe you've definitely struggled with these issues when running a bakery or pastry shop. Sometimes the dough ends up being inconsistent—either too thin, too thick, or unevenly rolled. That's why a commercial dough sheeter is so indispensable in professional bakeries and high-volume kitchens. Designed to replace labor-intensive hand-rolling, this machine transforms dough balls into uniformly thin sheets—perfect for pastries, thin-crust pizzas, croissants, and laminated doughs. Unlike basic dough rollers, which focus on speed, dough sheeters prioritize precision, offering adjustable thickness settings (often as fine as 1mm) to ensure consistent results and maintain a high standard in commercial bakery kitchens.

Built with stainless steel rollers and heavy-duty motors, these machines handle everything from delicate gluten-free dough to sticky sourdough without tearing, making them essential for both artisanal bakeries and large-scale operations.

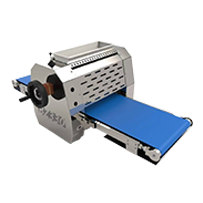

As an essential bakery equipment, countertop dough sheeters are compact, portable, and ideal for small bakeries or cafes with limited space. They typically process 10–15kg of dough per hour, perfect for boutique croissants or weekly pastry batches. In contrast, industrial floor models dominate commercial kitchens, boasting widths up to 520mm and capacities exceeding 50kg/hour. These giants are built for high-output tasks like mass-producing frozen pizza bases or puff pastry sheets.

Manual sheeters require operators to feed dough by hand, offering granular control for specialty items like phyllo or gluten-free crusts. Automatic models, equipped with conveyor belts, streamline repetitive tasks—ideal for 24/7 bakeries or chains prioritizing speed. For example, a croissant factory might use automatic sheeters to maintain consistent layering during peak production.

The magic lies in its roller system. Dough is fed between two rotating cylinders, which press and stretch it into a sheet. Thickness is adjusted via dials or digital controls, while scrapers prevent sticking. Advanced models include reverse functions to correct uneven edges. Actually, automatic models are equipped with conveyor belts that streamline the feeding process, making them incredibly popular in the baking industry. This not only increases efficiency but also ensures that the dough is evenly rolled without manual intervention. For laminated doughs, some sheeters integrate chilling systems to keep butter layers intact, critical for achieving the flaky texture of croissants.

When you go to buy a dough sheeter for your baking business, you might find a very similar machine: the dough roller. I bet that can definitely be confusing. So in this part, I'll show you the key differences between the two. A dough roller prioritizes speed over precision. Unlike dough sheeters, which meticulously control thickness through adjustable rollers, dough rollers use fixed cylinders to flatten dough quickly. This makes them perfect for rustic breads, pie crusts, or bulk pizza bases, where minor inconsistencies don't impact quality. These machines thrive in high-volume bakeries or pizzerias that churn out hundreds of rolls daily, sacrificing exactness for raw efficiency.

Laminated doughs: A dough sheeter's adjustable rollers create precise, paper-thin layers essential for croissants and puff pastry. By automating the folding process, it achieves 27+ butter layers without manual labor—critical for French patisseries aiming for flaky perfection.

Phyllo or strudel: Delicate doughs like phyllo demand sub-millimeter accuracy. Commercial sheeters gently stretch dough to 0.2mm thickness without tearing, a feat impossible with hand-rolling or basic rollers, ensuring crisp baklava or apple strudel every time.

Gluten-free baking: Gluten-free doughs crumble under harsh handling. Sheeters apply controlled pressure to maintain structure, preventing dense textures in sensitive recipes like almond flour tart shells or vegan puff pastry.

Automated Efficiency: Modern sheeters integrate timers and preset programs, allowing bakers to multitask. For example, a bakery can simultaneously sheet croissant dough while filling éclairs, slashing prep time by up to 40%.

Match dough hydration to machine settings: Sticky doughs require slower roller speeds to avoid tearing.

Clean daily: Wipe flour residue with a soft brush; never hose down electrical components.

Lubricate weekly: Apply food-grade oil to gears and bearings to prevent wear.

Since SHINELONG was established in Guangzhou in 2008, we have made great strides in the fields of commercial kitchen planning and kitchen equipment manufacturing.

IF YOU HAVE ANY QUESTION,PLEASE CONTACT US.

WhatsApp: +8618902337180

WeChat: +8618924185248

Telephone: 20-34709971

Fax: +86 20 34709972

Email: info@chinashinelong.com

After-Sales Contact

Whatsapp :+8619195343796

Email: service@chinashinelong.com

Add: No. 1 Headquarters Center, Tian An Hi-tech Ecological Park, Panyu Avenue, Guangzhou, China.