Bakery Production Line Supplier & manufacturers | SHINELONG

What is the production process of a bakery?

It consists of a series of steps including mixing, fermentation, makeup, proofing, baking, cooling, slicing and packaging. Due to their critical role, these processes must be carefully operated to meet pre-set conditions and specifications.

Product Introduction

Bakery Production Line

Application

The style and type of bread dictate the dough system to use as well as the processing conditions during mixing, makeup, and baking. A baker would not like to produce ciabatta with a close crumb structure, or to produce a loaf of white pan bread with an open crumb structure and texture like a ciabatta.

All steps in bread processing are important for a successful operation, but most bakers would agree that the three truly vital process steps are mixing, fermentation and baking. They are commonly described as the heart and cornerstone of breadmaking operations and can also determine the finished product characteristics, both internally and externally.

Mixing

The objective is the blending and hydration of dry ingredients, air incorporation, and gluten development for optimum dough handling properties. Variables to monitor and control include mixing time, energy input, dough temperature:

Mixing time: a function of flour strength, its protein, damaged starch and non-starch polysaccharides, and bran particle content. Other factors include mixer speed, mixing arm design, dough size in relation to mixer capacity, adequacy of refrigeration system (dough temperature), and delayed sugar/fat/salt addition.

Mixing equipment: vertical (planetary), spiral (open and closed for vacuum mixing), horizontal, continuous (open and closed).

Process specifications: 9–15 minutes at high speed in horizontal mixers. Final dough temperature should be 76–82°F (25–28°C).

Fermentation

The objective is yeast growth, production of CO2, ethanol, and organic acids, development of flavors and aromas, and modification of dough handling properties. Variables to monitor and control include fermentation time, temperature, titratable acidity (TTA), pH, and microbial count:

Fermentation time: controlled by the temperature of dough, sponge, starter or pre-ferment, hydration level (free water), pH, osmotic pressure, yeast food (amino acids, minerals, fermentable sugars) and yeast level (or lactic acid bacteria count).

Fermentation equipment: troughs in the fermentation room, closed tanks, open tanks, benches.

Process specifications: 1–20 hours (at room conditions), depending on the dough system used. The temperature in fermentation rooms is typically set between 75–85°F (24–29°C) with relative humidity (RH) of 60–80%.2

Makeup

The makeup stage mainly encompasses four operations:

Dividing

Rounding

Intermediate proofing

Sheeting and moulding

The divider cuts the bulk dough into single pieces of proper weight (with as little stress exerted on the dough as possible) so that these can be rounded and rested prior to taking their final shape. The divider must process the entire dough load quickly to prevent excessive gassing that creates scaling errors.

The sheeter and molder encompass the sheeting stage, curling chain, pressure board, and guide bars. These influence the gas bubble structure, shape, and length of the dough piece to place in the pan. The molder should be adjusted to achieve the desired shape with a minimum amount of pressure and stress on the dough to avoid damaging the cell structure obtained during mixing and fermentation.

Baking

The objective is to convert raw dough into bread, the set structure of the product, crust, and crumb formation, kill-step, and shelf-life extension. Variables to monitor and control include temperature, and time (governed in continuous ovens by conveying speed). Other relevant variables include heat flux (burners), humidity (dampers), and air velocity or flow.

Baking time: controlled by oven temperature, conveying speed, initial (proofed dough) and final product temperature, heating pattern, bake loss, product load, and formulation.

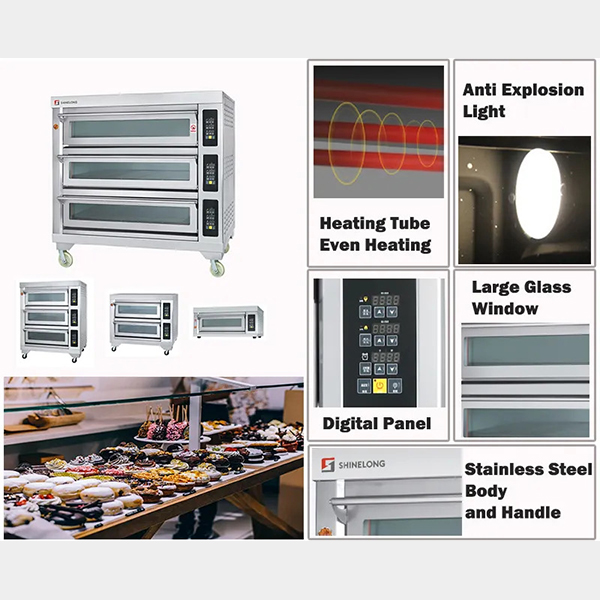

Baking equipment: direct-fired oven, indirect-fired oven, electric oven, rack oven, reel oven, conveyorized, tunnel, hybrid, and impingement oven.

Process specifications: 10–20 minutes at 400–420°F (204–216°C) (heating pattern in different ovens must be equivalent for comparable results).

Frequently Asked Questions about professional kitchen supplies

- Year Established2008

- Business TypeManufacturing Industry

- Country / RegionTianan Headquarters Center, No.555 North Panyu Avenue, Donghuan Street, Panyu District, Guangzhou

- Main IndustryFood & Beverage Machinery

- Main Products

- Enterprise Legal PersonJean Yang

- Total Employees201~1000 people

- Annual Output ValueUSD 17,000,000

- Export MarketEuropean Union,Middle East,Eastern Europe,Latin America,Africa,Oceania,Japan,Southeast Asia,America

- Cooperated CustomersMarriotts,Hilton,Ramada,Gahna Hospital,etc

Since 1998, Shinelong Group has started as a stainless steel workshop.

In 2008, Shinelong began to establish a professional service office and a Furnotel brand center after realizing the importance of brand uniqueness. The team consists of more than 50 people, with 25 in the pre-sales and after-sales service department, 4 in the product development department, 3 in the quality control department, 3 in the marketing department, and the rest in the support department. Since then, Shinelong has been committed to manufacturing professional commercial kitchen equipment and providing A to Z solutions for the F&B, catering, and central kitchen industries. By 2025, the company's services have been delivered to over 130 countries across the Middle East, Africa, Asia, and Oceania, with more than 2,800 successful cases.

Shinelong hopes to be a worldwide leading enterprise devoted to commercial kitchen equipment solutions. And Furnotel hopes to be a global leading brand of China commercial kitchen equipment.

Since SHINELONG was established in Guangzhou in 2008, we have made great strides in the fields of commercial kitchen planning and kitchen equipment manufacturing.

IF YOU HAVE ANY QUESTION,PLEASE CONTACT US.

WhatsApp: +8618902337180

WeChat: +8618924185248

Telephone: 20-34709971

Fax: +86 20 34709972

Email: info@chinashinelong.com

After-Sales Contact

Whatsapp :+8619195343796

Email: service@chinashinelong.com

Add: No. 1 Headquarters Center, Tian An Hi-tech Ecological Park, Panyu Avenue, Guangzhou, China.