SHINELONG Kitchen Equipment-A leading supplier of turnkey kitchen solutions in the hospitality and catering since 2008.

Guide to Shop Supplier Hotel Equipment in Shinelong

Supplier Hotel Equipment is one of the main products of Guangzhou Shinelong Kitchen Equipment Co., Ltd.. It has various designs which integrate compelling aesthetics and functionality, giving a real edge over competitors. It has a relatively long service life and performs well during its service life. Thanks to its good performance and strong functionality, the product can be applied in many fields and has a promising market application potential.

Shinelong branded products have been built on a reputation of practical applications. Our past reputation for excellence has laid the groundwork for our operations today. We maintain a commitment to continually enhance and improve the high quality of our products, which successfully help our products stand out in the international market. The practical applications of our products have helped boost profits for our customers.

Customer service is our priority. At SHIENLONG, we are committed to delivering with speed, courtesy and reliability! All of our Supplier Hotel Equipment products are 100% guaranteed. We provide customers with product customization, sample delivery and logistics choices.

Hospital kitchens, hospital catering, and food service play a vital role in healthcare facilities, impacting everything from patient recovery and staff efficiency to visitor satisfaction. Unlike typical food service businesses, hospitals have a multitude of considerations when it comes to catering. Healthcare catering demands precision in nutritional science, operational flexibility, and unwavering safety — all while adapting to technological innovations and rising patient expectations. Let's delve into what defines, drives, and evolves this critical service.

What is Hospital Catering?

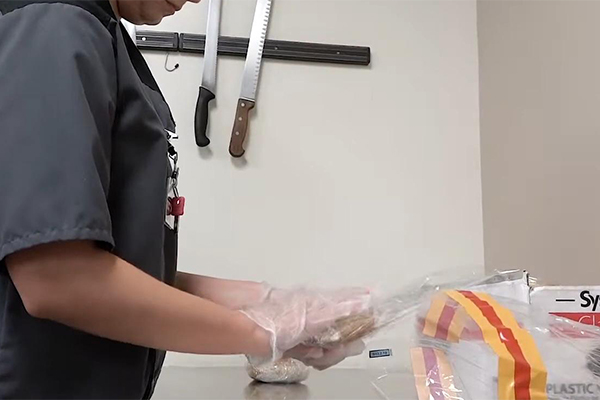

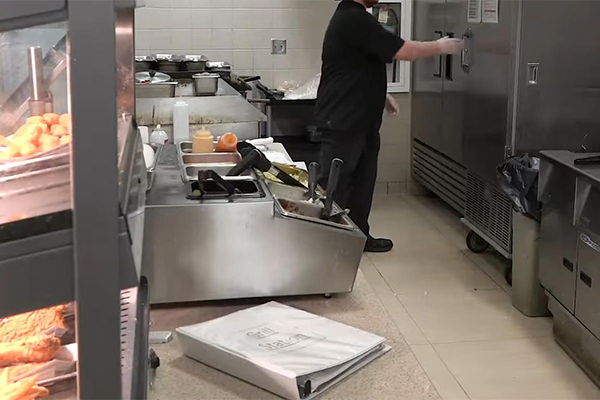

Hospital kitchen management runs the full meal journey from ingredient sourcing and prep to delivery systems, serving patients, staff, and visitors around the clock. The kitchen department in hospital facilities operates 24/7, balancing clinical nutrition rules with mass meal production demands. Specialized hospital catering equipment like combi ovens, blast chillers, and allergy-safe prep stations handles thousands of daily meals efficiently. Therapeutic diets address specific medical needs—think renal-friendly plates or diabetic-adjusted portions. Staff grab nutritious ready-to-eat options during marathon shifts, while visitors access comforting meals during stressful hospital visits.

The Importance of Hospital Catering

Nutrition: Fueling Recovery

Balanced nutrition remains clinically essential in healthcare catering, where proteins rebuild tissue, micronutrients boost immunity, and carbohydrates sustain energy reserves. Collaboration between kitchen teams and dietitians tailors menus to medical diagnoses—pureed textures address dysphagia, high-protein plates support post-surgical recovery, and calorie-dense portions combat oncology-related weight loss. Standardization proves ineffective: cardiac patients' strict low-sodium requirements contrast sharply with pediatric IBD nutritional protocols. Such precision directly correlates with reduced recovery durations and readmission rates across healthcare facilities.

Hygiene and Safety: Ensuring Well-being

Hospital food service equipment must comply with NSF/FDA standards, though protocols extend further. Facilities enforce HACCP through biometric access controls, ATP swab testing for hospital catering equipment, and color-coded utensils to eliminate cross-contamination. Every kitchen equipment for hospitals selection—from antimicrobial flooring to dishwasher temperature sensors—targets pathogen containment. In catering for hospital environments, single lapses risk immunocompromised patients; documented 0% foodborne illness rates result from rigorous staff certification and digital traceability systems.

Menu Options: Catering to All

Dietary diversity serves therapeutic purposes rather than convenience. Halal, kosher, vegan, and texture-modified meals constitute essential components for patient dignity and nutritional compliance, not alternatives. Leading hospital catering services cycle through 300+ monthly dishes, incorporating patient feedback to introduce culturally resonant options like congee for East Asian elders or injera for Ethiopian communities. Third-party religious audits verify compliance, with inclusivity driving consumption rate increases of 40% in peer-reviewed facility studies.

Food Service Quality: Enhancing Experience

Nutritional value diminishes through delayed delivery or temperature mishandling. Strategic meal timing aligns with clinical schedules—post-chemotherapy nausea windows, for example—using GPS-tracked heated trolleys. Staff food service kiosks achieve under 90-second fast delivery via contactless systems. Post-discharge satisfaction metrics continually refine services, evidenced by tablet-based bedside ordering implementations. True efficiency in food service within healthcare facilities prioritizes human factors over industrial output.

The Future of Hospital Catering

Hospital catering suppliers are pioneering AI-driven resource optimization, where predictive algorithms analyze admission patterns to adjust ingredient procurement—reducing waste by 18% in clinical trials. Next-generation hospital food service equipment like precision sous-vide systems and automated cook-chill lines. Turnkey kitchen solution providers like Shinelong exemplify sector transformation, offering modular steamers and ventless hoods enabling rapid infrastructure upgrades without construction downtime—a critical advantage for infection control compliance. During global health crises, agile hospital catering suppliers who master this balance of regulatory adherence and configurable design emerge as essential partners.

Proven in 200+ global hospital projects, including partnerships with Asia's leading healthcare providers, Shinelong's solutions are built on a foundation of innovation, scalability, and compliance with international safety regulations. Backed by 24/7 global support, agile R&D, and a client-centric ethos, we empower hospitals worldwide to transform their kitchens into high-performance hubs where patient care, staff productivity, and sustainability converge. Trusted by 200+ healthcare facilities, Shinelong redefines excellence in medical foodservice - because when lives depend on precision, nothing less than perfection will do.

Disinfection cabinets are kitchen equipment that many kitchens and restaurants are equipped with now, especially this year's epidemic outbreak. Although the epidemic in our country has been well controlled, the awareness of disinfection must be taken more seriously than before. But do you know? There are many tableware that are not suitable for being put into the disinfection cabinet. The following editor will introduce it to you. 1. Plastic tableware Plastic tableware is not resistant to high temperatures and cannot be put into high-temperature disinfection cabinets, because the temperature of high-temperature disinfection cabinets can reach 120 degrees when powered on, which will directly melt the plastic. 2. When colored porcelain tableware is glazed, the glaze and pigments of colored porcelain tableware contain heavy metals, which are easily diluted when encountering high temperatures. Therefore, do not use high-temperature disinfection cabinets to avoid diluting harmful substances and endangering human health. 3. Melamine tableware Melamine tableware is also not resistant to high temperatures. High-temperature disinfection can easily damage the original characteristics of tableware. In addition, melamine tableware must be cleaned before being put into the disinfection cabinet. 4. Long-term high temperatures of wooden products can also easily cause wooden tableware to crack, so wooden bowls, wooden chopsticks, and wooden soup spoons should not be heated in high-temperature disinfection cabinets. Keywords: school canteen kitchenware, canteen stainless steel kitchen equipment, school kitchen renovation project, Guangzhou kitchenware factory.

As long as food is prepared in the kitchen, heat will be generated. Once heat is generated, the chef will feel hot and sweaty, and will wipe the sweat while cooking, which will affect the speed of serving the food, and the serving time will be greatly reduced. So what are some small ways to avoid this kind of situation and make the kitchen cooler? Chain restaurant kitchen 1. Use range hood to cool down: Usually people only know that range hoods are used to absorb oil, but they don’t know that range hoods can also cool down. As long as the right exhaust is selected, the temperature of the kitchen can be controlled. The premise of using range hoods to cool down is to have "strong suction power". The cleaner the oil smoke is sucked, the heat in the kitchen will also be doomed. When installing the range hood, the distance from the countertop should not exceed 70 cm, and the kitchen smoke duct should not exceed 3 meters at most. These two size restrictions are to achieve the best effect of oil smoke absorption. Ensure that the oil smoke does not dissipate and the kitchen temperature will not be particularly high. 2. Focus on eliminating open flames: In fact, the most direct way to cool down the kitchen is to use gas stoves as little as possible, and use ovens, microwave ovens, induction cookers and other kitchen utensils that have no open flames, less smoke, and fast cooking to cook, which fundamentally eliminates the source of fire. I believe some people have roasted firewood before. When the firewood is ignited, you can clearly feel its temperature. The bigger the fire, the stronger the heat. Therefore, using induction cookers is definitely a good way to prevent heatstroke and keep the kitchen cool. 3. Take a visual cooling method: In the summer kitchen, color is the first appearance. Using calm and gentle colors can easily make people feel cool. Natural colors are the first choice. Food colors and plant colors can also make people relax. The second appearance is design. Simple and clean cabinet design will sweep away the irritable mood caused by the heat. 4. Use central air conditioning integrated ceiling: When decorating the kitchen, you can consider whether to install air conditioners or electric fans in the kitchen to achieve the effect of cooling. For kitchens that use open flame stoves, using electric fans may cause flames and oil smoke to spread, and the surface of the electric fan will soon be covered with oil smoke. The air conditioner also faces the same problem. The air conditioner covered with oil smoke will affect the cooling effect. Therefore, the air conditioner should be installed in a suitable position, integrating the air conditioner with the kitchen ceiling, and solving the kitchen cooling problem in one stop. Keywords: Guangzhou galvanized steel ventilation project.

With the development of the times, the catering industry has now transformed from the original small kitchen to a large commercial kitchen, and various kitchen equipment is emerging in an endless stream. From the original stove to the commercial kitchen that needs a complete set of kitchen equipment to operate, the use of large-scale kitchen equipment will inevitably mean that the kitchen equipment is becoming more and more standardized. So what precautions should be taken for commercial kitchen equipment? Let's take a look at it today. 1. Commercial kitchen space All kitchens need a certain space, whether it is home or commercial. For commercial use, there should be a slightly larger space because there are many people and many items, and the small space will appear very chaotic. 2. Commercial kitchen goals Determine the goal. Commercial kitchens generally make food for customers, and their purpose is to make money. Only after we have clarified this goal can we be more reasonable in the design of the entire commercial kitchen project. It will not cause waste in decoration. 3. The direction of commercial kitchens is different from the Western catering culture, so there will be a certain gap in the kitchen, so when designing commercial kitchen projects, we must consider the development direction. 4. Commercial kitchen location The location of the kitchen should be well selected. It is generally recommended to be on the back of the entire building or in the basement. If it is a basement, ventilation measures should be taken. 5. Reasonable kitchen design When designing a commercial kitchen, efficiency must be taken into consideration. Therefore, there should be a certain order between each area, which can greatly improve the efficiency of food preparation. 6. Commercial kitchen tableware Kitchen tableware is indispensable in all kitchens. Generally, commercial kitchen tableware should be practical as much as possible. Unless it is needed to create a special kitchen, it is generally easy to clean, has a long life, and is safe, energy-saving and efficient. 7. Commercial kitchen emissions When making food, it is inevitable to produce fumes and sewage, and the emission of fumes and sewage must be reasonably designed. If there are problems every other day, the business will also be affected.

Author:SHINELONG-Commercial Kitchen Equipment Solutions Suppliers

Sustainable Sourcing of Raw Materials for Manufacturing Commercial Cooking Equipment

Are you a chef or a restaurateur looking for the best cooking equipment while also staying true to your commitment to sustainability? Look no further! In this article, we will explore the concept of sustainable sourcing of raw materials for manufacturing commercial cooking equipment. We will delve into the importance of responsible procurement, the benefits of sustainable materials, and the innovative approaches being adopted by manufacturers in the industry. So, let's begin our journey towards a greener and more sustainable future for the culinary world.

Understanding Sustainable Sourcing

Sustainable sourcing is a term that refers to the procurement of raw materials in an ethical and environmentally responsible manner. It involves considering not just the quality and functionality of the materials, but also their environmental impact throughout their lifecycle. When it comes to manufacturing commercial cooking equipment, sustainable sourcing becomes crucial in order to minimize the negative effects on the planet.

Why is Sustainable Sourcing Important?

The foodservice industry is one of the largest contributors to carbon emissions and environmental degradation. By adopting sustainable sourcing practices, manufacturers can play a vital role in reducing their carbon footprint and preserving the Earth's resources. Sustainable sourcing also ensures that the manufacturing process aligns with corporate social responsibility policies and meets the demands of consumers who are increasingly conscious of the environmental impact of their purchasing decisions.

The Benefits of Sustainable Materials

When it comes to manufacturing commercial cooking equipment, using sustainable materials brings several benefits. Firstly, sustainable materials are often derived from renewable sources, reducing our dependence on finite resources. For example, manufacturers may opt for stainless steel made from recycled content instead of virgin steel. Secondly, sustainable materials tend to have a lower carbon footprint and produce fewer greenhouse gas emissions during their production. They also have a longer lifespan, leading to reduced waste and a decrease in overall environmental impact.

Another advantage of sustainable materials is their potential to enhance energy efficiency. Manufacturers can integrate innovative designs and eco-friendly materials that improve thermal conductivity and insulation, resulting in more energy-efficient cooking equipment. This not only benefits the environment but also reduces energy costs for chefs and restaurant owners. Ultimately, using sustainable materials can contribute to a more sustainable and profitable business model.

Innovative Approaches in the Industry

Manufacturers in the commercial cooking equipment industry are constantly seeking innovative approaches to enhance their sustainability practices. One such approach is the use of bio-based materials, derived from agricultural waste or renewable plant sources. These materials offer a sustainable alternative to conventional materials without compromising on performance or durability. For example, bio-based plastics can be used in the production of cooking utensils and equipment parts, reducing the reliance on petroleum-based plastics.

Additionally, manufacturers are investing in research and development to explore novel materials with improved sustainability attributes. For instance, advancements in ceramic coatings for cookware have resulted in non-toxic and eco-friendly options that are more durable and have excellent non-stick properties. By embracing these alternatives, manufacturers not only reduce their environmental impact but also provide chefs with healthier cooking options.

The Role of Certifications and Standards

Certifications and standards play a crucial role in driving sustainable sourcing practices in the commercial cooking equipment industry. They provide guidelines and benchmarks for manufacturers to adhere to, ensuring that their materials and manufacturing processes meet specific environmental and social criteria. Some prominent certifications in this field include Forest Stewardship Council (FSC) certification for wood-based products and Cradle to Cradle (C2C) certification, which evaluates materials based on their ecological impact and recyclability.

Manufacturers that actively seek these certifications demonstrate their commitment to sustainable practices, giving chefs and restaurateurs the assurance that their equipment is ethically sourced. By choosing products with recognized certifications, businesses can contribute to a more sustainable and responsible culinary industry.

Conclusion

In conclusion, sustainable sourcing of raw materials for manufacturing commercial cooking equipment is a vital aspect of creating a greener and more environmentally conscious culinary industry. By adopting responsible procurement practices and utilizing sustainable materials, manufacturers can significantly reduce their carbon footprint, conserve resources, and provide chefs with more energy-efficient equipment. Innovations in materials and manufacturing techniques, coupled with certifications and standards, are propelling the industry towards a more sustainable future. So, let us embrace these practices and play our part in creating a healthier and more sustainable planet, one delicious meal at a time.

.Recommand:

Since SHINELONG was established in Guangzhou in 2008, we have made great strides in the fields of commercial kitchen planning and kitchen equipment manufacturing.

IF YOU HAVE ANY QUESTION,PLEASE CONTACT US.

WhatsApp: +8618902337180

WeChat: +8618924185248

Telephone: 20-34709971

Fax: +86 20 34709972

Email: info@chinashinelong.com

After-Sales Contact

Whatsapp :+8619195343796

Email: service@chinashinelong.com

Add: No. 1 Headquarters Center, Tian An Hi-tech Ecological Park, Panyu Avenue, Guangzhou, China.